|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Pumps | >For hygienic applications |

For hygienic applications

02 December 2014

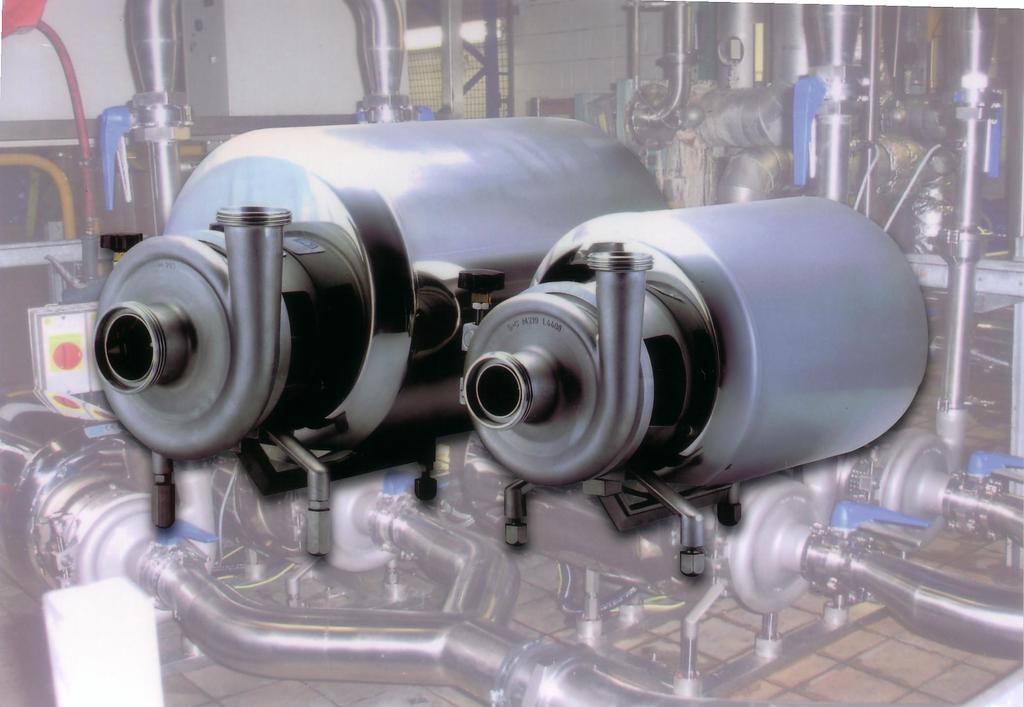

Transferring liquids in food, brewing, pharmaceutical and other similar hygienic process applications requires easy-to-clean, easy-to-maintain smooth, stainless steel pumps without dead areas and traps. A company offering a range of pumps for these situations is Pump Engineering.

For example, the CSF-CS, CSA and CSM centrifugal pumps are capable of handling capacities from 1 to 550m3/hour at heads up to 155m.

CSF pumps are made in investment cast AISI 316L stainless steel, with stainless steel for all wetted parts. They feature a 6 vane impeller which facilitates the handling of ‘challenging’ liquids, for example syrups for soft drinks and those containing particles or small solids.

The pumps are designed for CIP (Clean-in-Place) to ensure the absence of dead areas and feature electro polished finishing of all surfaces. CSF pumps are available with standard or ATEX certified motors, these are back pull-out design and fitted with a quick-release clamp to enable fast and simple dismantling.

The CSA version has an electro polished finish to 0.5m Ra and is approved to US FDA 3A standard or European EHEDG standards, with an aseptic version available for pharmaceutical applications.

Depending on the duty CSF-CS and CSA pumps can be supplied with an internal or external single mechanical seal or flushed double mechanical seal for handling high temperature liquids, or those with a tendency to crystallise. Elastomers are available in a choice of Viton, EPDM, silicon or PTFE.

Typical applications for CSF-CS hygienic pumps include transferring syrups, sugar solutions, flavourings, salad washing, alcohols, beer, milk, oils, vinegar, fruit juices, high purity water, CIP solutions, suspensions, yeast and melted butter.