|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Lubrication | >Saving on lubrication costs |

Saving on lubrication costs

26 November 2013

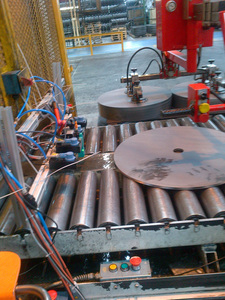

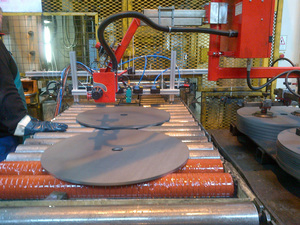

GKN Land Systems, which lubricates the disks of about 1500 tractor wheels a month, is hoping to reduce oil use by 50% and improve safety by eliminating the risk of spillage by switching from a manual, brush-applied lubrication method to the spray.xact bar-mounted system, developed and supplied by technotrans.

Ray Rowley, tooling engineer, says: "Applying lubricant to the product with a coarse brush is an uncontrolled process and uses far more oil than needed which has both cost and environmental implications. By switching to the spray.xact we can apply lubricant in a controlled way which will halve our oil usage and promote a safe, uncontaminated and healthy environment for the operator."

The spray.xact model measures and applies lubricant using a nozzle which doesn’t require compressed air, minimising spray mist. Each nozzle is independently controlled so the operator can dictate when the spray starts and ends and adjust the quantity and frequency. It can apply work to assymetrical components as well as flat surfaces.