|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Cooling equipment | >Chillers chosen |

Chillers chosen

29 September 2017

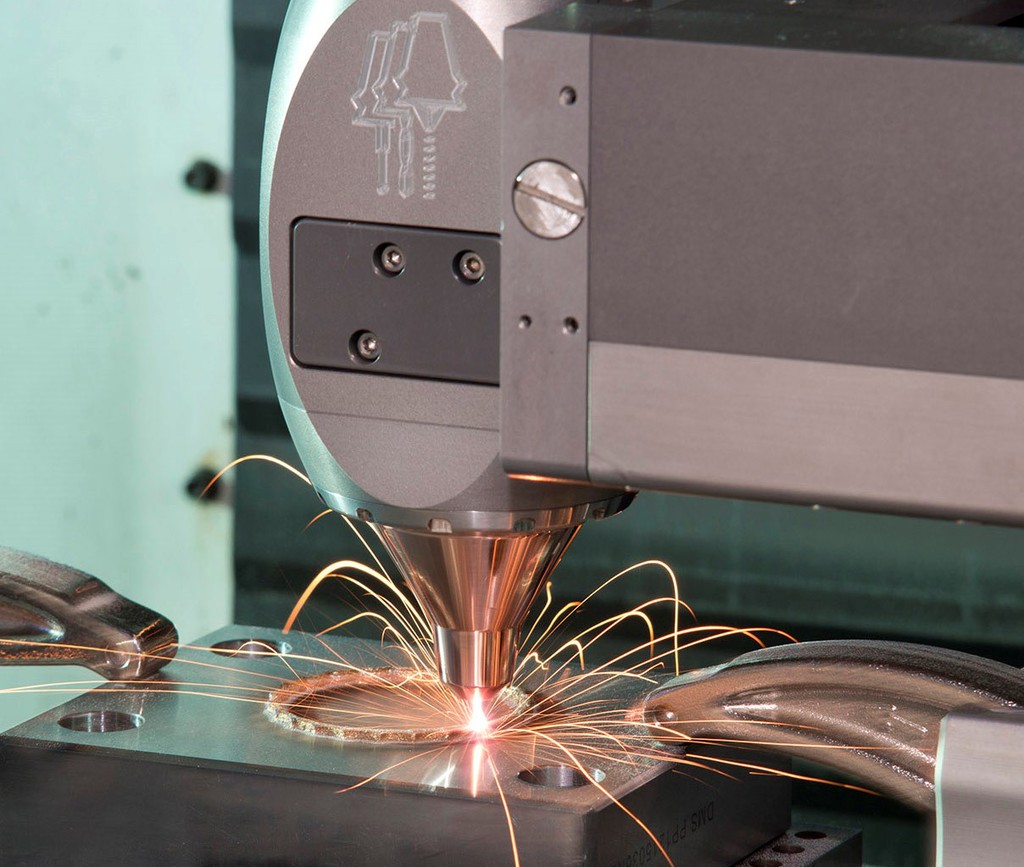

A company which specialises in combining additive manufacturing and subtractive engineering (3D printing and milling) has turned to technotrans for Termotek chillers and the first assignment of an anticipated 36 cooling circuits a year have been delivered.

“We need to chill the laser, optics and 3D heads which can require three different reservoirs and this is what Termotek/technotrans could provide,” says Peter Coates, technical director at HMT. “Each element might need a different size of cooler so the tailored solution approach made sense.“

Of the first four chillers supplied, two will be used in Germany and two in Colombia. HMT will supply globally and here again the technotrans worldwide sales and service support network was critical.

The chillers provided to HMT are compact and have a relatively low cooling capacity. However, the technotrans group also works with customers in the plastics, chemical, food and general process industries on projects providing complete bespoke containerised megawatt cooling plants. These are designed with a plug and play installation in mind.