|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Bearings | >Anti-corrosion coating |

| Home> | Efficient Maintenance | >Bearings | >Anti-corrosion coating |

ARTICLE

Anti-corrosion coating

17 February 2014

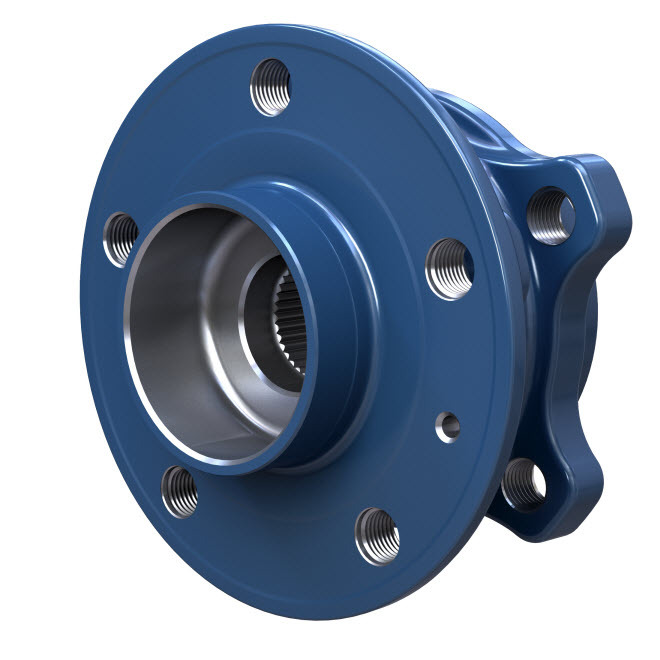

SKF's new anti-corrosion coating for hub bearing units makes disassembly of the bearing from the knuckle and rim easier. It also improves the aesthetics of the bearing during vehicle life and at the same time prevents rusty surfaces from coming into contact with the seals.

The coating has been designed to withstand more than 400h of salt-spray test (DIN EN ISO 9227 NSS) without jeopardising the geometrical tolerances of the hub bearing unit. It can be applied to all flanged hub bearings units of second and third generation.

Features include: Scalable layer thickness according to customer requirements, low thickness tolerance, maximum working temperature in excess of 200°C, and UV paint.

MORE FROM THIS COMPANY

- Testing to overcome motor failures

- Steeled for success

- Induction heater for large bearings

- New European aeronautical test centre

- Large sealed spherical roller bearing off to Peru

- Ongoing quest for better bearings

- Collaboration agreement to develop use of active magnetic bearing applications

- Going to extremes to deliver savings

- Spindle service

- Pneumatically driven piston pump

OTHER ARTICLES IN THIS SECTION