|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Workholding solutions |

Workholding solutions

24 January 2014

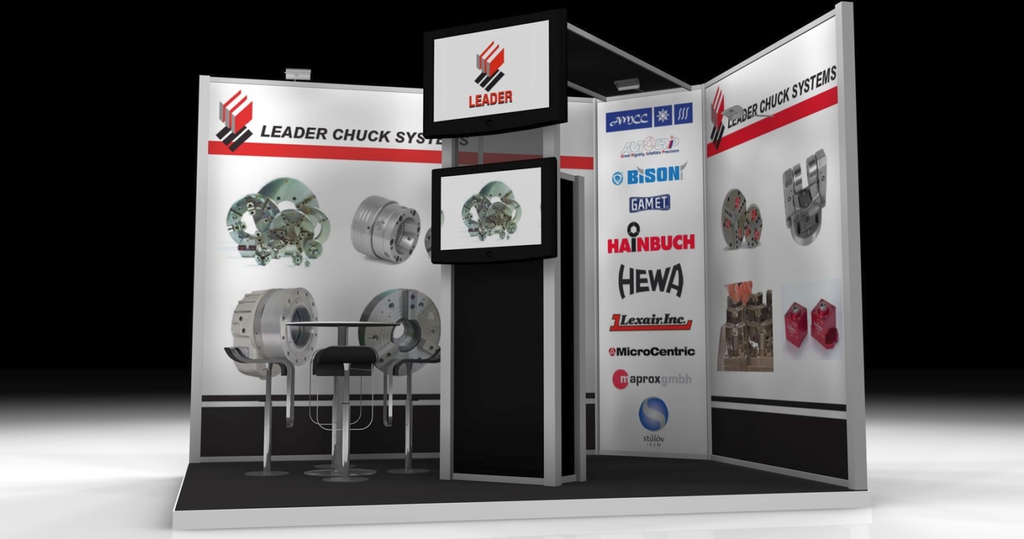

At this year’s Southern Manufacturing exhibition Leader Chuck Systems will demonstrate workholding solutions from a number of its partners.

These will include turning application solutions from AutoGrip, Bison and Hainbuch. Effective answers for stationary fixturing problems will also be highlighted, with the recently launched ZeroClamp zero point clamping system taking centre stage.

Designed to reduce set-up times and increase machining efficiency, the ZeroClamp system provides an effective route to producing more components, quicker and at a lower cost. Using the face and taper HSK spindle tooling principle the system can achieve a repeatability of ±2.5 micron.

As the hollow, tapered-shank bolt is drawn into the clamping pot the elastic properties of the seating ring expand slightly, allowing the taper to locate positively and the faces of the pot and the pallet or raw material to engage and locate solidly. Subsequently each fixing point has a break-out force of up to 60 kN. Stand Q106