|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Quality and tolerance testing | >Sensors for testing impact protection |

Sensors for testing impact protection

17 March 2014

As D3O's products are used in soft body armour for motorcycling, skiing and other sports, as well as industrial and military applications, consistent quality control is essential; from its earliest days, D3O’s laboratory has used Kistler Instruments’ sensors for product development testing and quality control.

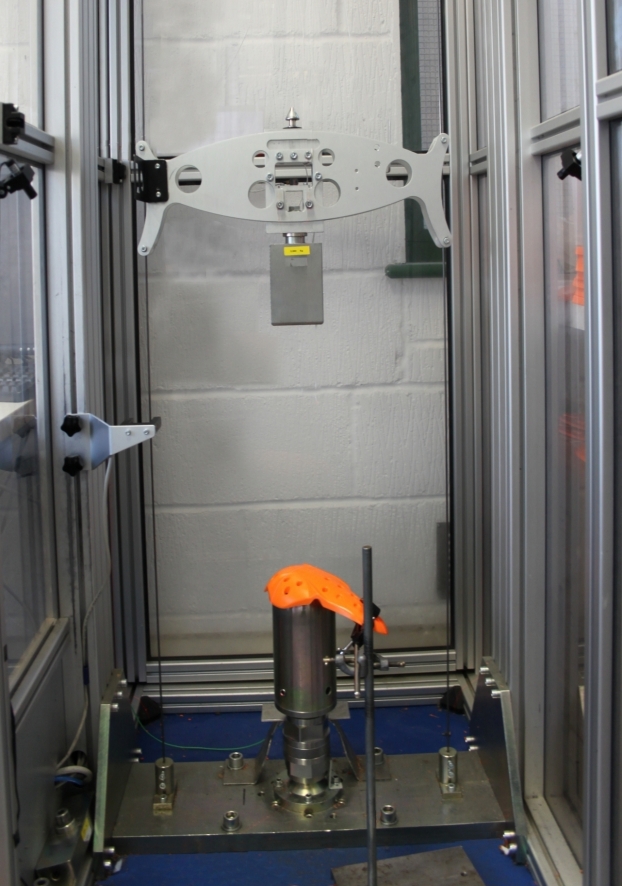

Currently, the company uses a triaxial accelerometer and a force sensor specially calibrated to 25 kN, both by Kistler, in an impact test rig used by the company’s development department. The test rig specification is defined by BS EN 1621-1:2012 requirements and test methods for motorcyclists' clothing to protect against mechanical impact, especially limb joint impact protectors.

Process development manager, Chris Meadows, explains that D3O has used Kistler sensors for product testing since the very beginning. Reliable and accurate testing is essential, not only to meet the British Standard but to ensure that the company’s products always provide the protection needed in what might be life-threatening situations.

As D3O continues to expand into new market sectors ranging from skiwear and laptop cases to military applications, quality assurance is paramount to maintain the company’s reputation for quality and consistent performance. The reliability and precision of Kistler’s sensors is helping it meet the demanding standards of new markets and applications.

- Free injection moulding seminar

- Modular multichannel charge amplifier

- Pressure sensors for ATEX zones

- High speed torque sensor

- Modular absolute pressure sensor

- Kistler 3-component force sensor with measuring range to 450kN

- Miniature sensor for very low force measurement applications

- Piezoelectric dynamometer

- Rotating torque sensor has wireless signal transmission

- Monitoring for zero defects