|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Software | >Combines energy and process data |

Combines energy and process data

20 June 2014

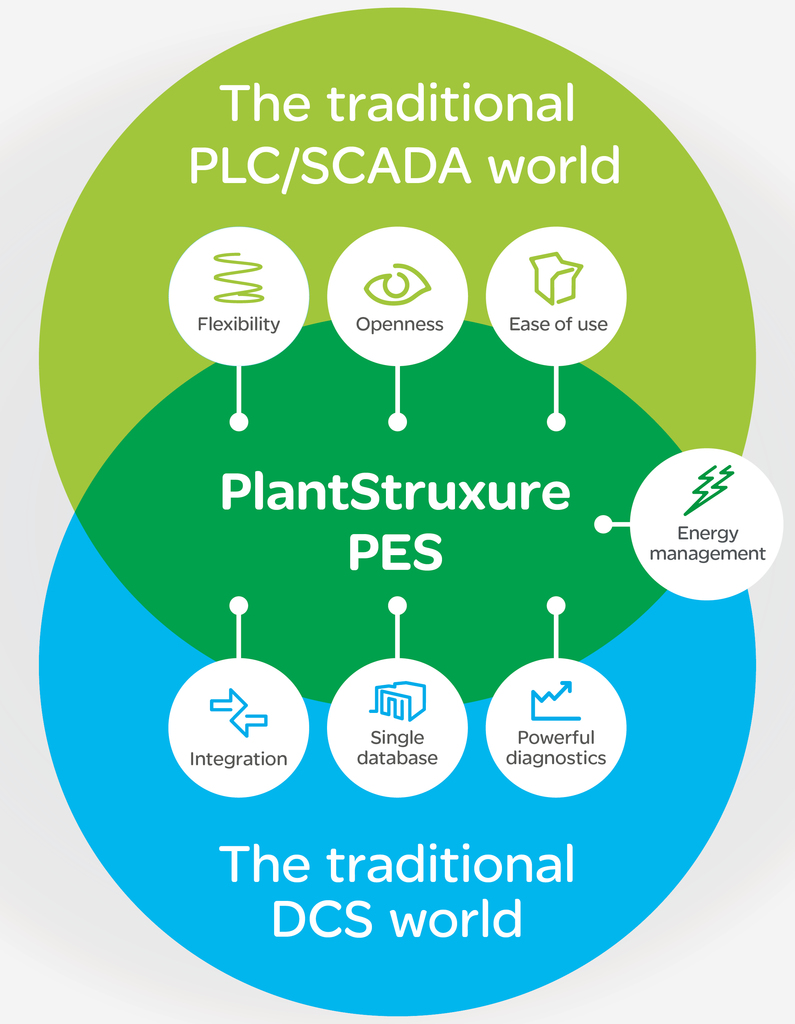

PlantStruxure Process Expert System (PES) from Schneider Electric is a Distributed Control System (DCS) that combines the ease-of-use and openness of PLCs and SCADA with the integration, single database and powerful diagnostic capabilities of a traditional DCS, to form an energy-aware DCS.

PlantStruxure PES leverages integrated software, open Ethernet architectures and powerful object libraries to create a holistically optimised production process. By combining energy and process data in a single integrated platform, plant operation teams are provided with a real-time control and operational interface to help them make informed decisions that will reduce energy consumption and increase process efficiency.

The new solution also supports plant digitisation as it puts key process data at the fingertips of operator and maintenance teams. Through special navigation services, the right person can get the right information at the right time, speeding up diagnostics, cutting downtime and bringing productivity to a whole new level.

Furthermore, PlantStruxure PES captures and presents data on one easy-to-use interface, adding intelligence by giving operators a complete picture of the production process.

The system also gives new insight into plant efficiency, enabling plant operators to meet production and energy KPIs by presenting process and power information together. By actively automating energy management, it is easier to eliminate energy waste at the source of overconsumption, delivering savings of up to 30%.

Jez Palmer, business development manager, at Schneider Electric, comments: "PlantStruxure PES is a leading-edge offer in the field of process automation systems, bringing the best from the PLC, SCADA and DCS worlds and combining them with integrated energy management features which deliver superior value throughout the lifecycle of a plant.

"The system’s tight integration ensures efficiency from design engineering through operation. Engineers can develop the configuration faster and more accurately and maintenance teams can diagnose and solve problems faster to reduce downtime at a facility.”

- ISO 50001 accreditation

- Drives range expanded

- New Energy Opportunities network expands to Europe

- Water and Wastewater Leadership Forum launches

- Pump energy performance improved

- A new era of industrial computing

- Collaborative approach

- IIoT and Digitisation: the future of Industrial Process Safety

- On course to meet carbon neutral target

- Predictive maintenance and decision support