|

Edward Lowton

Editor |

|

New Heraeus Oven Combines Infra-Red with Convection and Optimum Quartz Glass Reflection

17 April 2014

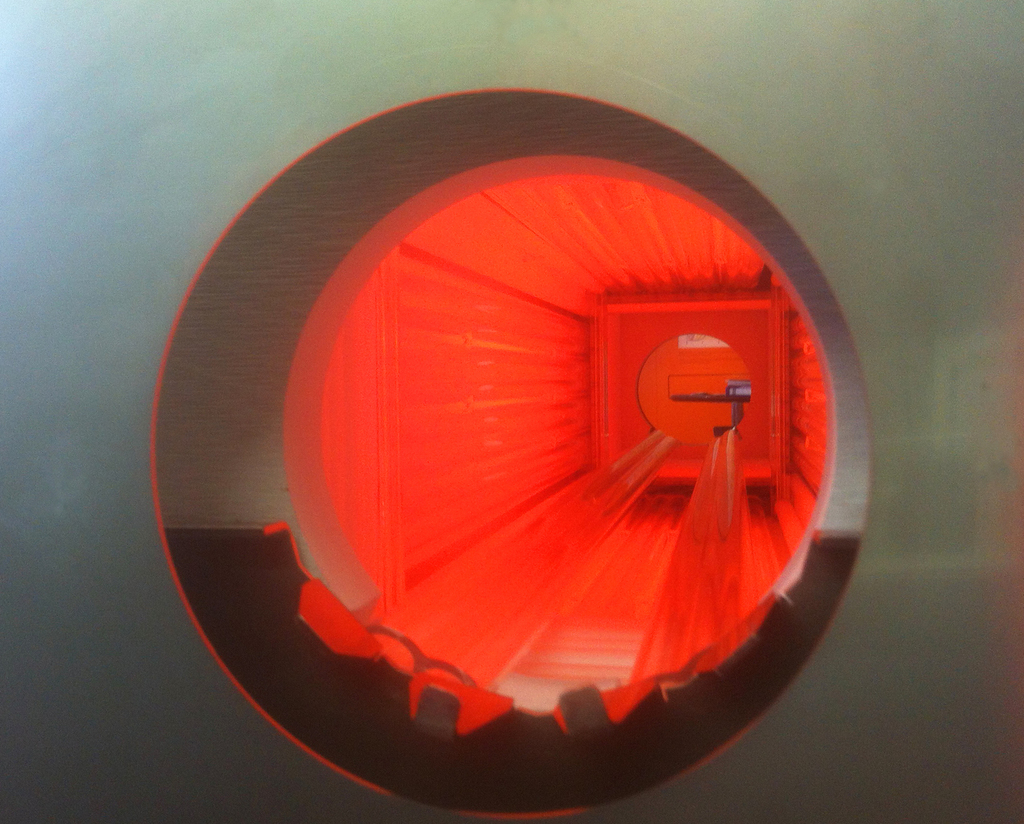

The new MAX oven from Heraeus Noblelight combines infrared radiation with natural convection and optimum heat reflection to provide a compact, efficient solution for high temperature processes.

The ovens can be matched exactly to the heating profile required, and are said to offer increased capacity and improved product quality compared with conventional ovens, while saving space, time and energy. As such, the new oven is well suited for processes such as the tempering of glass, enamelling, coating of metals, heating of sensitive or highly reflective materials and sintering of ceramics.

MAX infra-red ovens use quartz glass materials with QRC (quartz reflective coating) reflectors. Developed by Heraeus, the QRC reflector features opaque white quartz glass, whose nanostructure imparts a diffuse reflective capability to the material, resulting in a very high homogeneity of the temperature field. This means that it is possible to achieve a temperature difference within a heated product of just ±2°C. Quartz glass is extremely heat resistant and can withstand the attack of acids and other aggressive substances. It is said to have excellent mechanical stability, even at very high temperatures. In addition, the quartz lining ensures a high purity, heating environment for sensitive materials.

Because the infra-red and natural convection heating is reflected optimally within the oven, maximum process temperatures of up to 900°C can be reached in less than 10min, with similar times for cool down. A holding power of just 3kW is all that is required to maintain the maximum process temperature. Consequently the ovens allow fast product change-over and are suitable for both batch and continuous operation.

MAX ovens are tailored to meet specific process or product specifications. Computer simulation at the design stage optimises the energy efficiency and the infrared emitters are precisely matched to the heating needs. They can be arranged in sequence and individually controlled and can be easily shaped to allow flexibility in oven dimensions.

- Infra-red heating system

- Infrared heating improves factory throughput

- Heraeus infra-red ensures polymer-polymer bonding in roofing manufacture

- Short wave system

- Fast reponse infrared heaters

- Warming role at chocolate maker

- Line speed boosted

- Compact infrared print dryer

- Chocolate moulds get pre-heat treat

- National Composites Centre uses advanced CAE technology