|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Oil analysis | >Fluid analysis |

Fluid analysis

15 January 2015

Exol Lubricants has launched a new fluid analysis service to help eliminate the risk of machines failing prematurely.

Fluid Check allows machine operators to regularly monitor the condition of the lubricating fluid they’re using in a bid to detect the type of contaminants and wear issues that can cause early machine failure.

Operators simply draw a sample of fluid from their machine and send it to Exol for testing. Results are posted to a secure web-based portal that operators can access to download the test data. If the fluid needs to be changed, the data will tell the operator and they can schedule maintenance before a failure occurs.

Steve Dunn, Exol Lubricant’s sales director, said: "Our Fluid Check service makes it really easy for operators to get a rapid and clear picture of the quality of the fluid they’re using. If there is a deterioration in fluid quality that’s likely to cause a failure, Fluid Check will identify the problem and flag it up so that the necessary maintenance can be completed in good time.”

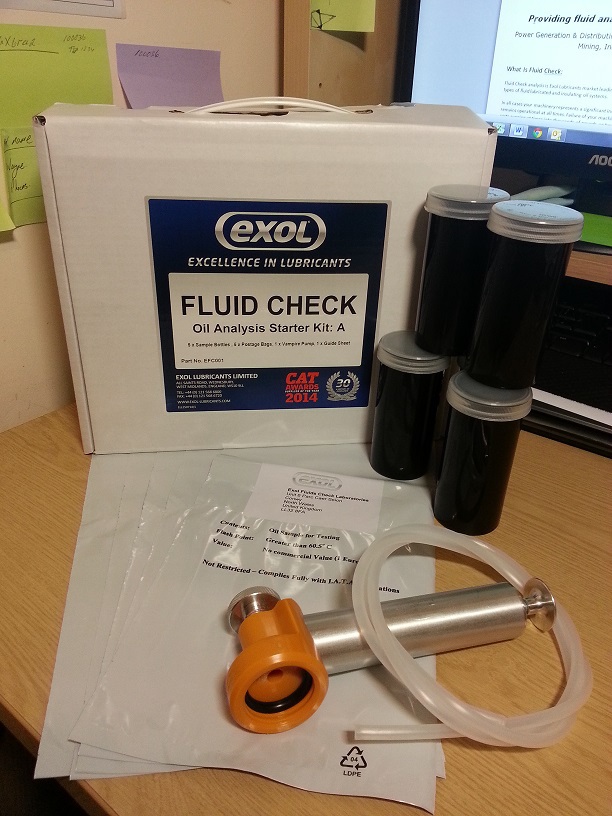

Each customer using Exol’s Fluid Check service is given a pack that contains all of the equipment that is required to draw off fluid samples safely and cleanly.

- No related articles listed

- Reducing Operating Costs and Improving CO2 Footprint in the Food-Processing Industry

- Playing a part in wear metal analysis

- Early warning

- Oil talks, but do you listen?

- Oil health check

- Oil particle sensor

- Care package upgraded

- Oil contamination seen as a key cause of machinery failure

- Service update

- Monitors changes in transformer oil