|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Lubrication | >Oil contamination seen as a key cause of machinery failure |

| Home> | Efficient Maintenance | >Oil analysis | >Oil contamination seen as a key cause of machinery failure |

Oil contamination seen as a key cause of machinery failure

27 June 2014

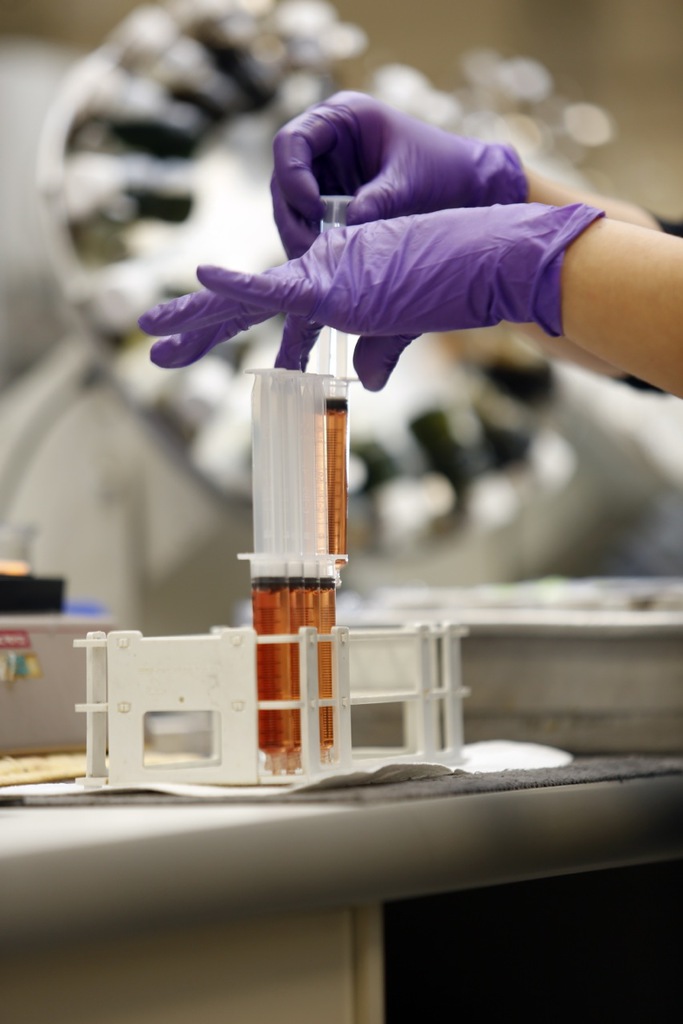

Between 70 and 80% of all hydraulic failures, that can lead to machinery failure, can be traced back to contaminated oil, according to Bosch Rexroth. The company believes lubricant analysis to be a vital part of modern maintenance and servicing.

The company has identified three types of oil contamination that can cause machinery problems: Solid particles such as dirt and dust; liquid contamination, such as water and other fluid mixture; and gaseous contamination, such as air.

"The origins of any contamination can vary,” says Chris Gray, an expert in oil contamination at Bosch Rexroth. "Contamination can be built-in during the manufacturing process, such as welding residue, or it can be external contamination entering via piston rods or poor seals and vents. It can even be generated during the working life of a drive via seal abrasion or chemical erosion.”

He continues: "Focused monitoring of oil cleanliness and conducting oil analysis provides information on the condition of the operating medium at an early stage and thus contributes to preventing expensive repairs, downtimes and unnecessary oil changes. Extended oil intervals cut costs in the short run, but in the long term, they increase the risk of damage caused by oil degradation.”

However, there remain concerns that oil analysis is not forming part of the regular machinery servicing schedule. "For many maintenance and production engineers there simply isn’t the time and manpower to conduct the regular checks needed to identify problems before it becomes too late,” says Gray. "This can lead to a whole host of problems, such as valve and pump failure, which can result in unplanned machinery downtime and potentially costly repairs or the need to replace components entirely.”

- Oil contamination: New report available

- Internet of Things innovators recognised

- Chance to learn about Lean

- Advanced tightening technology

- Offshore developments

- Too much maintenance remains reactive

- White paper on hydraulic filtration media

- Maintenance: an eye opener

- Manufacturers must do more to tackle poor ergonomic design

- Online hydraulics catalogue