|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Oil analysis | >Service update |

Service update

16 July 2014

More than 20 years after Q8Oils first launched its Field Service Technician (FST) service, the company has introduced QCare – a major upgrade of the system that monitors the condition of Q8Oils' metalworking fluids and lubricants in applications such as turning, cutting and grinding.

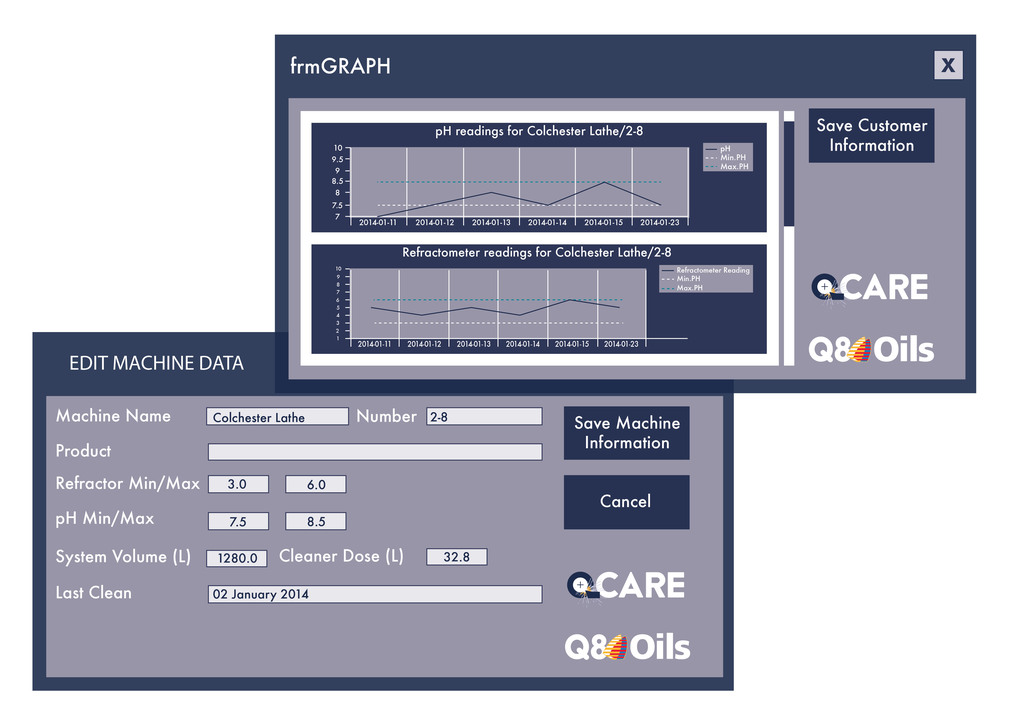

The new QCare service uses a network-enabled, tablet-based system with a bespoke ‘app’ that enables Q8Oils' field service technicians to monitor fluids, complete audits and deliver results while on site. In addition, because FSTs are highly trained metalworking experts, when working with machine operators they may be able to identify problems and help to rectify them.

A visual inspection and a variety of tests are conducted to ensure Q8Oils products are performing correctly. These include standard fluid parameters such as concentration, pH and microbiological content. They also offer advice that can help customers increase coolant life and optimise performance resulting in improved machining processes and reduced machine down time.

Customers can also log-on to the QCare system using their own tablet or desktop computer, and view a full historical report at any time, and share it with colleagues.

In the past 20 years the FST system has moved from a ‘paper’ system requiring everything to be written down and multiple copies made, to an advanced and automated ‘traffic-light’ system that identifies conditions as Green (normal), Amber (caution e.g. adjust fluid concentration) or Red (immediate action required).

Direct sales manager Jeremy Dineen explains: "The new QCare system is very much easier to operate, fully-automated and therefore much quicker, and will create a graphic chart to show a full history of any individual machine.” He adds that the new system is very compact, much more user-friendly on site, and allows data to be distributed instantly.

- Soluble cutting fluid

- Metal working fluids for modern manufacturers

- Fully-synthetic cutting fluid

- Snecma Safran aerospace approval

- Keeping the wheels of industry moving

- Powerful additive package

- Plant maintenance solutions

- Stable & longer lasting

- Care package upgraded

- Water soluble machining and grinding fluids

- Reducing Operating Costs and Improving CO2 Footprint in the Food-Processing Industry

- Playing a part in wear metal analysis

- Early warning

- Oil talks, but do you listen?

- Oil health check

- Oil particle sensor

- Care package upgraded

- Oil contamination seen as a key cause of machinery failure

- Fluid analysis

- Monitors changes in transformer oil