|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Quality and tolerance testing | >Simulation table |

Simulation table

05 May 2015

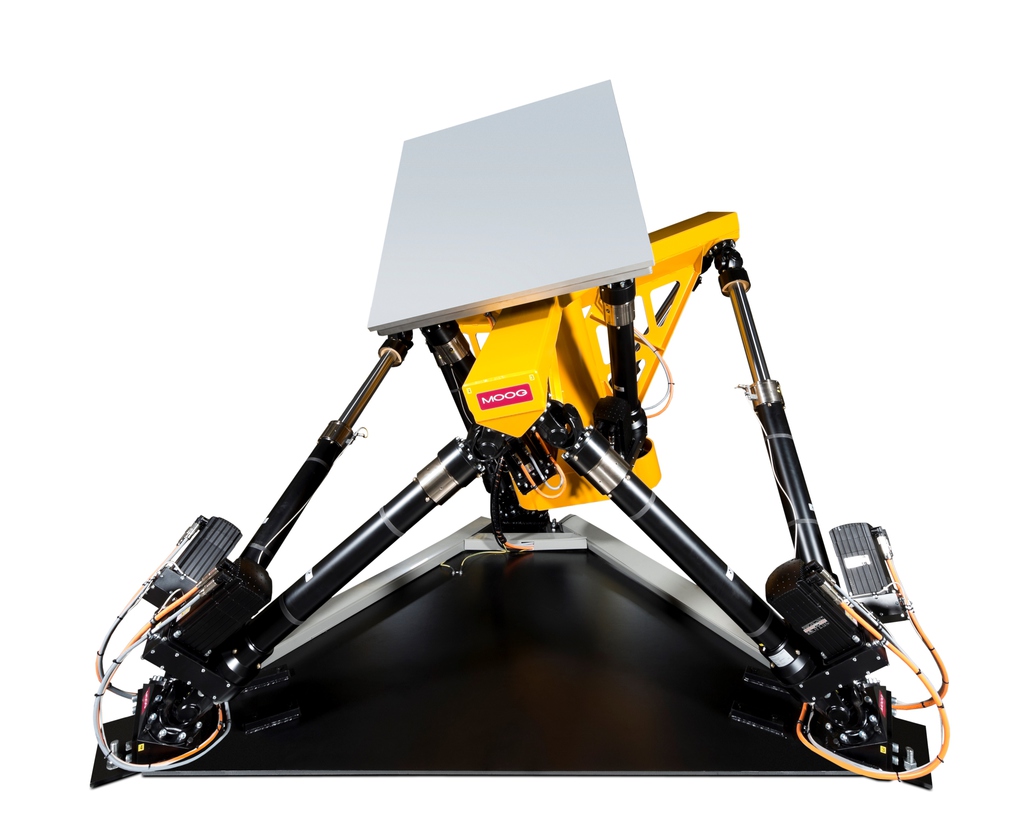

Moog Industrial Group was selected by Veritas AG to supply an Electric Simulation Table with Tilt for testing the behaviour of fluid in in automotive fuel and fluid tank systems, a test that requires large angular motions.

Veritas AG ordered the system to perform tests on automotive SCR (Selective Catalytic Reduction) fluid tanks that are used to inject liquid-reducing agents in catalytic converters for the reduction of harmful emissions.

The Electric Simulation Table with Tilt is designed to perform dynamic liquid sloshing tests, and can simulate real-world road conditions. The technology has already been adopted by Fiat Group Automobiles (FGA) for testing fuel tank systems. The behaviour of the liquid and components of the tank system can be tested and evaluated in a confidential laboratory setting, as opposed to a test track. The test results will allow Veritas AG to make the right choices when developing new fluid tanks. The company chose the Moog system because it is specially designed for this application, uses plug and play electric actuation technology and is easy to use and maintain.

The Moog test system is comprised of an Electric Simulation Table with an innovative additional tilt table on top for increased pitch and roll motion. The Electric Simulation Table is used to reproduce the higher frequency road profiles, where the tilt table can simulate the cornering and acceleration behaviour of the vehicle. This enables Veritas AG to include various conditions during driving that lead to extreme fluid-sloshing effects, such as instant braking or very sharp cornering manoeuvres. In addition, the Moog Replication test software module will enable Veritas AG to replicate and play out time history drive files that were recorded at the test track.

"We are pleased to see that the innovative Electric Simulation Table with Tilt is fully embraced by the market as the effective solution to simulate liquid sloshing behaviour and test fluid tank systems in a safe and controlled laboratory setting”, says Marie-Laure Gelin, Solutions marketing manager test and simulation at Moog.

An Electric Simulation Table is designed to perform product development tests and driver simulation research. Position, velocity and acceleration are controlled by the system through integrated control hardware and software. In addition to the electric actuators of the simulation table, the tilt table features two electric actuators for increased pitch and roll motions up to 30°. The total pitch and roll angles of the test system exceed 50°.

The Electric Simulation Table with Tilt is part of the Simulation Table product range, which also contains various hydraulic solutions for high frequency durability and fatigue testing. Tests that are typically performed with electric simulation tables include: Driving simulation, ride and comfort testing, qualitative evaluation of human response, vehicle components testing, NVH (Noise, Vibration and Harshness), BSR (Buzz, Squeak and Rattle testing), turret testing, antenna testing and medical research applications.

- Simulates acceleration & displacement inputs

- Wanted: Oldest operating servo valve

- Modular die cushion systems

- Fan-cooled brushless servo motors

- Structural test

- New solutions for auto test labs

- Integrated safety functions

- Test controllers for aircraft

- Two year warranty for MFB valves for industrial applications

- Electrohydrostatic pump unit offering extended