|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Conveyors | >Motorised drive solutions |

Motorised drive solutions

27 April 2015

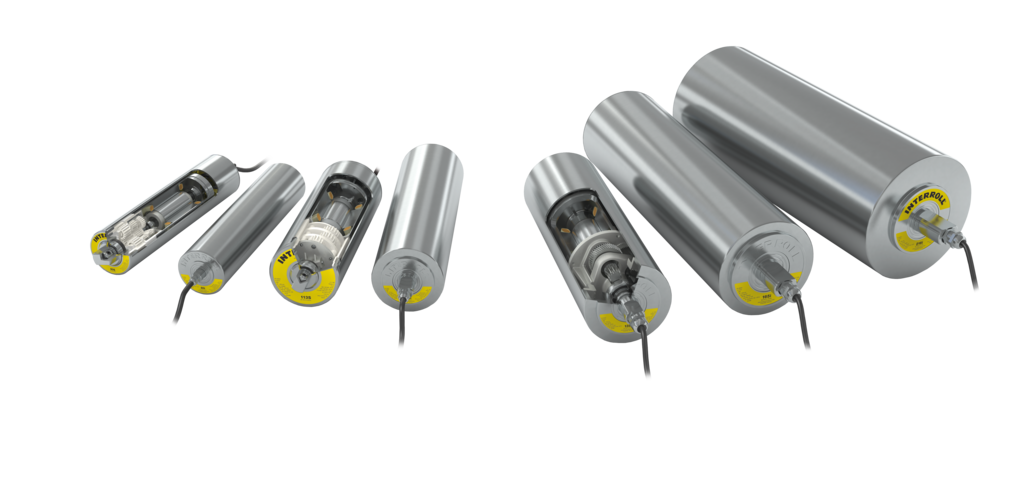

Interroll offer a diversified range of IP66/IP69K synchronous and asynchronous drum motors and IP54/IP66 24VDC RollerDrive, which are designed to provide a quick and easy way of building maintenance-free, hygienic and energy efficient belt conveyors, ZPA accumulation roller conveyors and associated material handling equipment.

No matter what the task or operating conditions, Interroll says its engineers will provide a cost effective solution to achieve the optimum materials handling system. It has adapted drum motors to suit customers specific handling applications and all types of belt conveyor systems including modular plastic belts, with FDA approved profiled rubber/ PU lagging, stainless steel or polymeric sprockets.

Highly energy efficient and sealed for life, Interroll drive solutions are resistant to dust, oil, grease and impervious to high pressure cleaning and are designed to give long life, trouble-free operation.

For companies still using conventional geared drives, Interroll engineers will provide a free capabilities demonstration of Interroll Drive Solutions at its Kettering factory showrooms or at a company's individual premises on request.

- Push back system

- Synchronous drum motor boosts salmon slicing

- Conveys and sorts efficiently and reliably

- Drum motors

- New managers in UK and South Africa

- Distribution centre automated

- Interroll intensifies exchange of expertise with digital channels

- Converts pallet racking into dynamic carton flow store

- Smart drive solutions and flexible conveyor modules

- Drum motors