|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Compressors & ancillary equipment | >Cutting energy consumption |

| Home> | Plant, Process & Control | >Compressors and ancillary equipment | >Cutting energy consumption |

Cutting energy consumption

01 July 2015

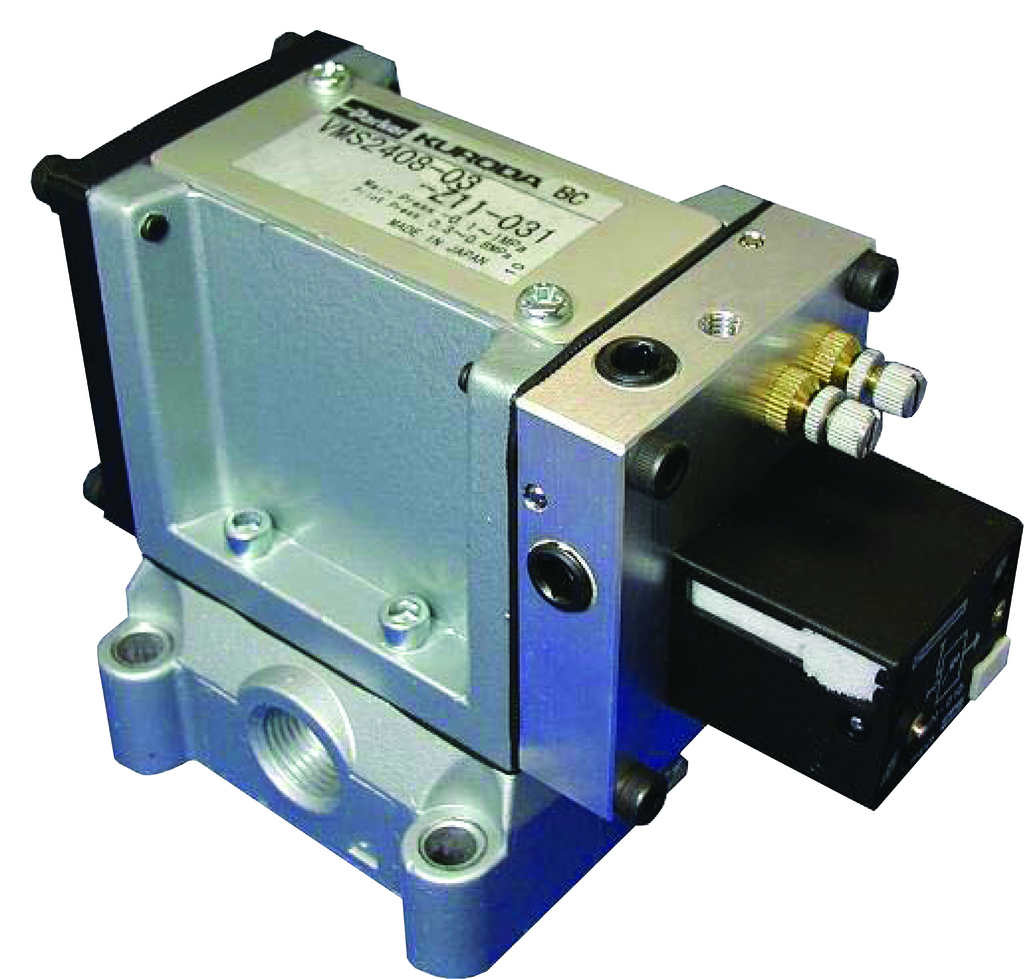

Parker Hannifin reports that its newAir Saver Unit can reduce air consumption by up to 50% and improve efficiency in air blow applications.

The company says that air blowing activities consume almost half of all compressed air used in plants? To help reduce this resource burden, the Air Saver Unit uses pulsed air technology. At its core is a switching valve that converts continuous air blow into pulsed air blow without the need for any additional external control. Put simply, it creates air that is blown in a series of high speed on and off pulses; when the blow is off, there is no air consumption, resulting in fewer tank recharging cycles.

Other benefits include savings in compressor power, a reduction in overall CO2 emissions and a significant contribution to energy-saving activities.

The Air Saver Unit is easy to install; at plants using electrically operated solenoid valves to control air blowing, the units can be quickly and easily retrofitted to straightaway deliver a reduction in air consumption with no significant system changes i.e. PLC program reconfiguration. For plants using manual ball valves, there are passive versions of the Air Saver Unit series; these do not require any electrical power.

In total there are seven models in the range, offering flows (at 5 bar) from 150 to 15,000 l/min.

- AC drives with power ratings to 450kW

- Video highlights capabilities and products

- Broader conductive materials array

- Which dryer technology?

- Helping cut energy consumption

- Enhanced programming capabilities

- Compressed air systems: Efficiency matters

- Closed-loop capabilities

- Latest firmware

- Software boost for Parker’s general purpose variable speed drives