|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Motors and drives | >Synchronous motor series: Tough and dynamic |

| Home> | Energy Management | >Motors and drives | >Synchronous motor series: Tough and dynamic |

Synchronous motor series: Tough and dynamic

17 August 2015

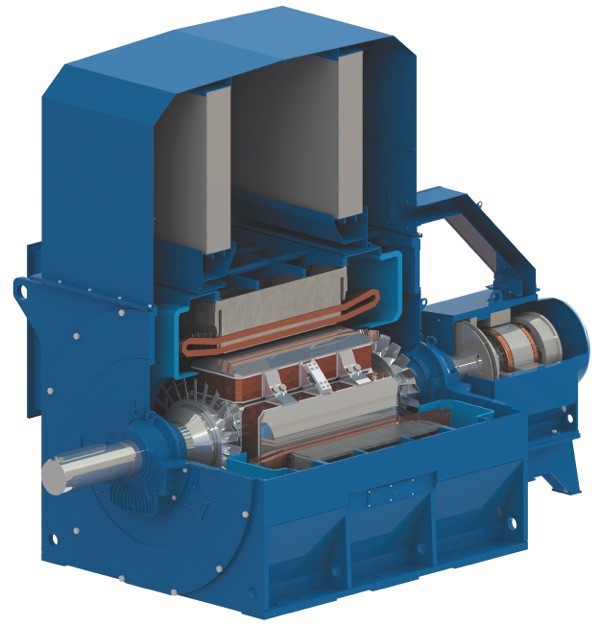

WEG has introduced a new series of synchronous motors – the SM40 series – for the power range 5 to 35MW. The motors are said to provide exceptional reliability in demanding applications with extended maintenance intervals, enabling users to reduce servicing costs and increase process uptime.

With shaft and rotor made from a single piece of forged steel and high starting torque, the SM40 is suitable for high-inertia applications including centrifugal compressors in air separation plants or the oil and gas industry, large fans in the steel industry or power plants, and high-power pumps and pulp mills.

The SM40 motor has a robust rotor construction with high mechanical strength and stability, and has been designed to eliminate the risk of detachment of individual pole shoes or pole mounting screws. The stator consists of high-quality, low-loss silicon steel laminations and top-grade bobbin windings insulated using a special vacuum/pressure impregnation (VPI) process while an optimised thermal design ensures uniform temperature distribution along the stator, prolonging the service life of the winding insulation.

The motors have a high starting torque and low starting current enabling users to achieve energy savings. WEG says the low starting current minimises the impact of the motor on the power supply network and means starting aids such as starting chokes, autotransformers or variable speed drives become unnecessary.