|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Warehouse IT | >Specialised traceability labels: Brady’s UltraTemp™ Label Series |

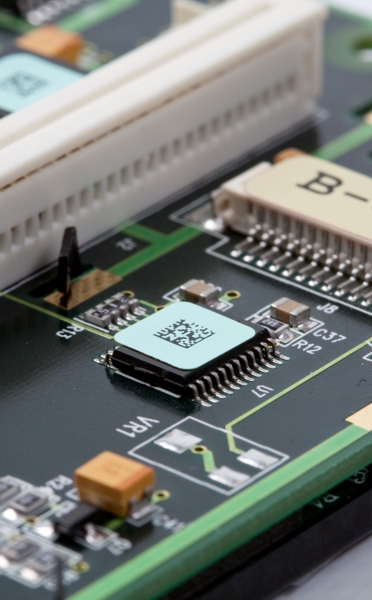

Specialised traceability labels: Brady’s UltraTemp™ Label Series

02 February 2016

Identification specialist Brady offers a completely automated and affordable traceability solution. The solution includes fast label printers, flexible label feeders, accurate label applicators and durable traceability labels. Brady’s traceability labels are developed specifically for traceability and include a brand of specialised labels to track & trace printed circuit boards: the UltraTemp™ Label Series.

Every label in the UltraTemp™ Label Series has been constructed with automatic application in mind. Using polyimide materials, Brady’s R&D Department constructed purpose-built labels for auto-apply and labeling of printed circuit boards. Equipped with ‘clean liner technology’, UltraTemp Labels adhesive cannot run into the press cut at excess temperatures. This eliminates downtime due to labels not being placed, or due to a fractured liner. Clean liner technology ensures a smooth production cycle even at high temperatures.

The performance properties polyimide-based labels provide are ideally suited to withstand the extreme demands of printed-circuit board assembly. On top of this, Brady’s UltraTemp™ Labels also feature an industry-leading adhesive formulation designed to withstand reflow and aqueous cleaning. Labels were

tested for heat, chemical, and abrasion resistance to ensure optimal performance in reflow, wave solder, and in harsh washing systems. Brady obtained compatibility reports from both Kyzen and Zestron, showing they can resist the newest cleaning chemicals used in printed circuit board production.

In addition to outstanding adhesive properties Brady’s polyimide label materials also exhibit excellent printability which ensures accurate scanning in a wide variety of production processes.

Brady's UltraTemp™ Labels are in line with substance restrictions as imposed by the EU REACH and EU RoHS legislation.

- Tailored asset & component labels

- Enabling safer machine interventions

- Easily enable a major leap in workplace efficiency

- Improve workplace safety and optimise your performance with the S3700

- Easy safety identification

- Improved safety sign printers

- 5S Plus Guide: Best practices for a leaner and safer workplace

- Go for zero with on-site safety sign printing

- Lockout/tagout solutions

- LED tag counts down to maintenance