|

Edward Lowton

Editor |

|

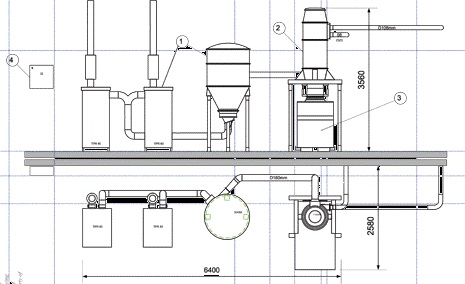

Centralised Vacuum system

05 February 2016

Dust/Chip Extraction - Cleaning - Material Transportation

We design the system to meet your needs. At Dustcontrol we have an extensive experience in designing and constructing innovative customised solutions ensuring that we can provide a high level of system integration and customer value.

How does Dustcontrol’s stationary vacuum system fit into the value chain?

Operational Efficiency

- Vacuum transport as a part of the manufacturing process

- Fewer breaks in the manufacturing process

- Shorter maintenance breaks

- Lower repair expenses

- Lower heating expenses

- More efficient waste management/ recycling

Health & Environment

- Cleaner and safer working environment

- Meet the demands of Health and Safety legislation

- Motivated and healthy employees

- Improved organisational culture

- Easier to recruit and retain staff

- Automated recycling

Quality

- Increased product quality by elimination of dust, liquid, or smoke at the source.

- Clean products ready for delivery or the next stage in the manufacturing process.

To attain the desired benefits with an extraction system, the system must be complete, from the suction casing to the vacuum producer. All the components of the system are equally important in implementing its functionality.

Vacuum Producers- Turbo pumps or Radial Blower

The vacuum producer is at the heart of the system. Here, the negative pressure is created that drives the system. In Dustcontrol extraction systems, the vacuum level is generally from 6-40 kPa.

Our normal source extraction and vacuum cleaning systems use turbo pumps. This device has an ideally suited characteristics capacity for this type of system. Vacuum level increases as more resistance is presented, an important quality in minimizing the possibility of blockages in the tubing system.

For applications involving fume and light dust, such as paper, radial blowers are used. These have larger air-flows and operate at a lower relatively constant, vacuum level.

Our turbo pumps and radial blowers have very high quality silencing.

Tubing System

The tubing system transports the material from the point of collection to the central unit. Dust is generally abrasive, some more than others, therefore the standard material thickness of the tubing system is 1,5 mm. Applications with fume and light dust use reinforced spiral duct. Stainless tubing systems and extra abrasion resistant fittings are also available.

Dustcontrol has a very comprehensive assortment of tubing fittings and installation hardware. This gives greater flexibility in design and installation of our tubing systems. Our mechanical jointing system makes alterations and additions very easy to carry out.

Work Place Equipment

An extraction system is sized for only those outlets which are to be used simultaneously. This is in order to maximize efficiency and minimize the size of the central unit. All outlets must have some type of closure, either a valve or shutter. These can be manually actuated, such as flap valves or manual shutter valves, or automatically controlled for actuation only when extraction is required.

Overhead suspension arrangements such as swing-arms and hose reels can increase the usefulness of the system, increase ergonomics and minimize potential trip hazards from hose left on the floor.

Control Systems

Motor starters and System Control Panels control the operation of the system, both operation of the vacuum producers and cleaning of the filter. A variety of other control functions can be installed as required.

Even with a rather basic control system, intelligent features can be included to clear coarse material in the main tubing runs or control vacuum producers and therefore save energy consumption according to actual requirements.

- No related articles listed