|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Vice and jaws working together |

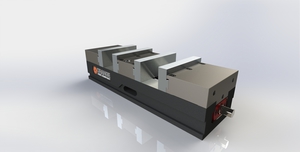

Vice and jaws working together

29 March 2016

Two of Leader Chuck System’s US-based partners, CARVEsmart and Orange Vise Company, have announced a collaborative technology agreement. Visitors to MACH 2016 can see the results on Leader’s stand.

Mark Jones, MD, explains: “Under the agreement, CARVEsmart, maker of the original quick-change vice jaw system featuring dovetailed jaw technology, and Orange Vise Company will form a special relationship that provide the latter with the opportunity to offer CARVEsmart patented features in the Orange Vise Integrated Jaw System (IJS). Both companies have recently made major investments in equipment as part of the venture.”

CARVEsmart dovetail and clamp features are machined directly into the Orange IJS vice eliminating the need for master jaws. This saves 38mm of opening. The 6in Orange IJS vice accepts all CARVEsmart dovetailed jaws. The fully machinable jaws result in a larger machinable workholding zone that permits holding larger parts deeper into the jaws of the vice for better performance.

The patented CARVEsmart system is designed for production and toolroom applications replacing the often cumbersome, conventional method of attaching vice jaws to a vice. Dovetailed jaw changes are fast and easy with the ‘from the top’ clamping system.

The clamp assembly pulls dovetailed jaws tightly into two axes while a SMARTstop pin locates the jaw accurately in the third axis promising ±7.5 micron relocation. The SMARTstop slot and pin is internal to the dovetail allowing vices to be mounted side-by-side.

Extruded aluminium dovetailed jaw stock is available in five profiles in lengths up to 2,400 mm. It can be cut to any length the user requires. Steel options are 60/62 HRc hardened tool steel, 48/50 HRc A2 machinable tool steel, and 1018 steel. Specialty jaws are also available.

Stand 5304

- Tailor-made solutions

- Quick change chuck jaws

- Quick-change vice jaw system

- Bespoke workholding solutions

- Tailor-made workholding and component manipulation solutions

- Leader outsources stock holding and distribution

- Magnetic workholding solutions

- Workholding solutions

- Precise coolant supply

- Multi-axis manufacturing