|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Conveyors | >Smart conveying systems keep tyres rolling |

Smart conveying systems keep tyres rolling

10 May 2016

Interroll components are designed to provide energy-efficient drive solutions to the tyre industry sector. Products include its 24V RollerDrive, a high-performance product for optimising production flows.

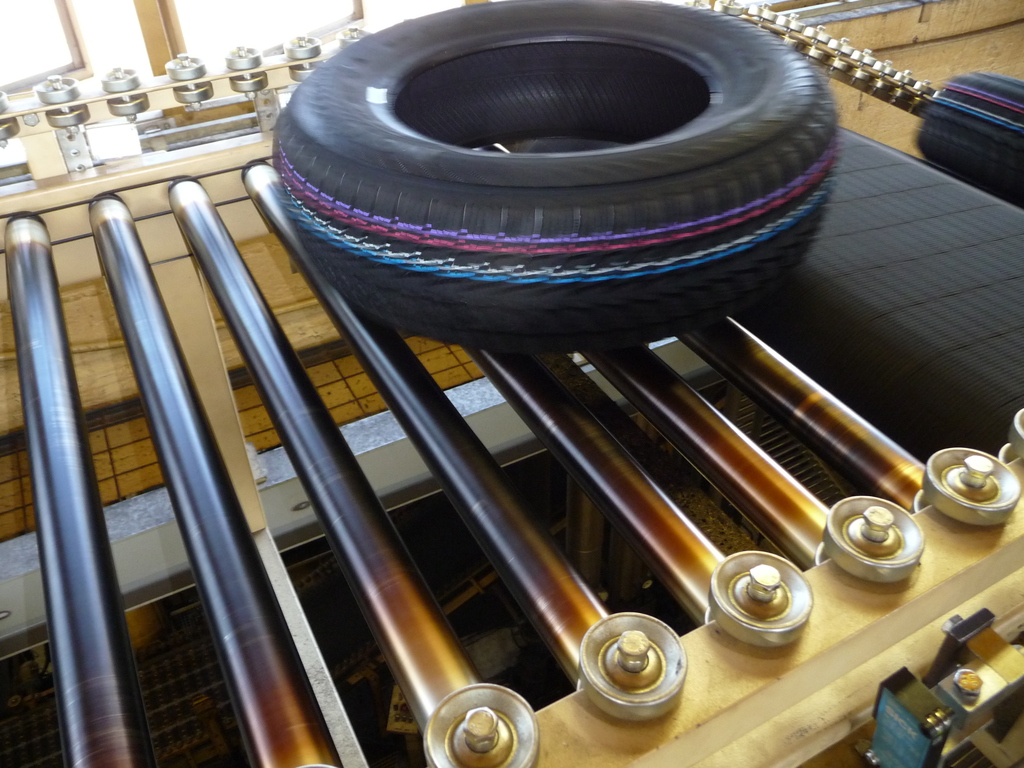

Roller conveyors can be used to speed up, slow down or accumulate products of various sizes and shapes, allowing these types of systems to operate as 'rolling warehouses'. For instance, they can be used for tyres of different weights and sizes.

Interroll's roller drive, which consists of a brushless 24V AC drive integrated into a conveyor roll, is suitable for various types of conveying systems. The basic purpose of the drive is to allow decentralisation and modularisation of zero-pressure accumulation conveyors. Interroll's roller drives allow materials to flow steadily and efficiently; they are said to feature low energy consumption and environmental impact, reduce maintenance and cut operating costs.

Interroll partners with systems integrators, plant engineering and construction companies to offer 24V conveying systems as a flexible solution for optimally automating distribution centres in the tyre manufacturing industry. The company says its solutions can generate energy savings of up to 50%.

Maurizio Catino, industry sales manager at Interroll's Automotive and Tyre division, says: "Given the growing competition and changing production specifications, the tyre manufacturing industry is particularly well-suited to expanding the use of automation to improve the efficiency, productivity, flexibility and cost-effectiveness of its plants."

The tyre industry is an important part of Interroll's vertical, global sales organization: "We understand the needs of tyre manufacturers and can supply innovative conveying and drive solutions that offer significant economic and environmental benefits," adds Catino.

Interroll works with leading systems integrators around the world and offers both a high-quality product and all technical expertise and support required to build tyre manufacturing plants, of which automated conveying systems form a key component.