|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Storage and containers | >'Stick and start' system for driverless AGV |

'Stick and start' system for driverless AGV

17 October 2016

BITO Storage Systems has introduced a driverless intralogistics transport solution that is easy to implement, adapt or remove and does not require any permanent fixtures.

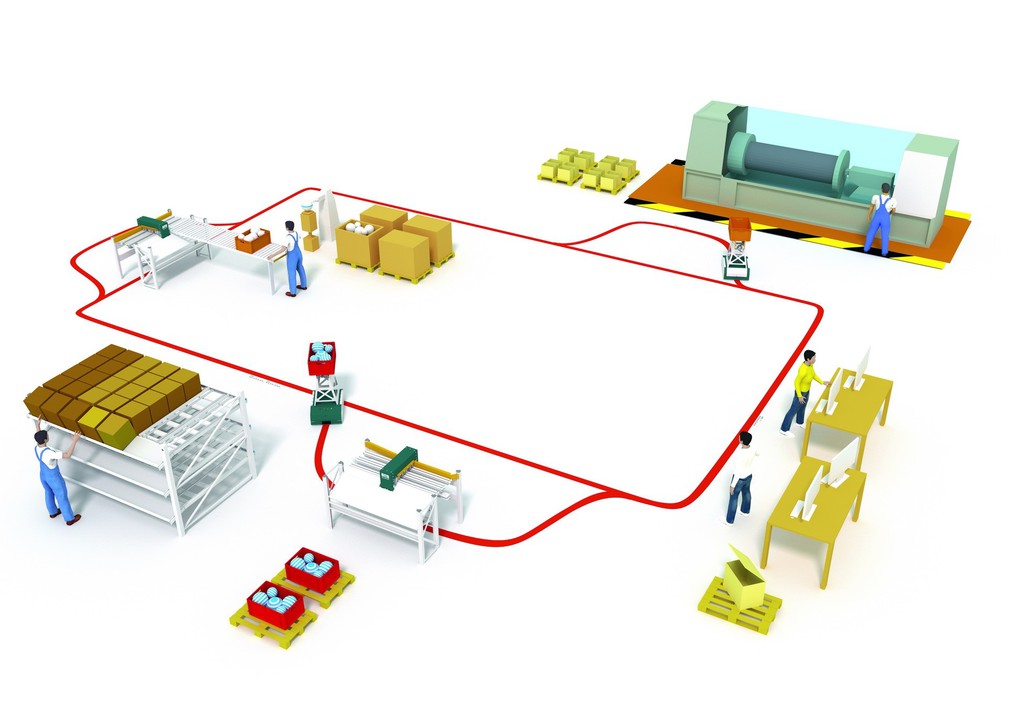

LEO LOCATIVE is a ‘low-level’ Automated Guided Vehicle (AGV) that simply follows tape laid on the floor, which can be added to or removed whenever required – It does not require a Wireless Local Area Network (WLAN) or a central control computer. This provides an agile, user-friendly option for all kinds of order picking operations and is said to be particularly useful for ecommerce, order picking peaks and assembly processes. LEO can connect production lines with the warehouse, receiving area and shipping area – reducing the risk of damage and the need for manual handling of heavy loads.

LEO transports loads to, or picks loads from, a transfer station – which can also be easily moved as required – for dropping off at other stations along the taped trail. The vehicles do not stop to be loaded or unloaded at the stations, which have load grippers and bin identification sensors to ensure the right bin is picked up or dropped off, providing a seamless flow. Filling levels are also recognised. This ensures fast and easy bin pick-up and drop-off wherever the items are required.

Because the easily adaptable LEO is not a permanently fixed system, warehouse or factory floor space is available for other uses when required. This makes it a suitable alternative to low-level conveyors for the internal transportation of bins and containers up to a maximum of 600 x 400mm and loads to 20kg.

Implementation is a simple ‘stick and start’ process: Red marker tape, which provides an optical track to guide LEO, is laid out as a closed loop. Navigation commands and tasks are transmitted via floor markers – adhesive signal transmitters placed along the path to provide LEO with information on the path layout, target points and operating commands. Target stations can be entered via a display and LEO’s e-ink reader will direct the vehicle to its target.

Proximity sensors detect obstacles and maintain a distance between vehicles. A stop and go sensor at its rear reactivates the LEO without manual intervention. When conditions change, such as increased pedestrian traffic, LEO reacts thanks to its speed control. There is also an emergency button to override the system.

LEO can be customised to specific needs, implemented rapidly and changed just as easily whenever required and without any external support.

- More room with racking

- Smart fit shelving

- Retrofitting advantage for order picking

- Quiet on conveyors

- Quiet on conveyors

- Meet BITO at Southern Manufacturing And Electronics 2024

- For large volumes

- BITO to spotlight highly productive solutions at IntraLogisteX 2020

- Productive order picking using multi-tier shelving

- Space efficient design and complete access