|

Edward Lowton

Editor |

|

Insulation savings highlighted

07 June 2017

According to an Ecofys study, the potential CO2 reductions that can be achieved by insulating the bare surfaces of pipework, tanks, vessels, ductwork and mechanical services equipment is equivalent to the output of 15 x 500MW coal fired power plants.

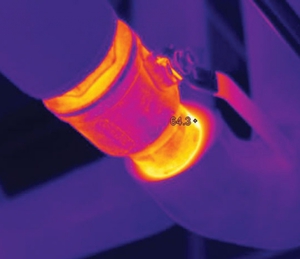

With the large energy saving potential possible, the choice of a high performance material is rewarded with rapid payback times, usually less than one year. Valves and flanges account for a higher proportion of energy usage than pipework equipment and therefore should be fully covered to minimise heat losses. The flexible nature of nitrile rubber materials (FEFs) such as Armaflex, ensure that valves, flanges, bends and pipe junctions can be precisely insulated using sheet material, without the need for separate fittings. The Armaflex Application guide details the patterns required to insulate various types of mechanical services equipment.

On cold process and industrial equipment, a key consideration is to prevent condensation and ice formation. The build up of condensation on low temperature process lines reduces system efficiency and eventually leads to ice formation, corrosion problems and damage to surrounding goods and equipment. To prevent moisture penetrating the insulation material and degrading thermal performance, closed cell materials offer comparatively thinner insulation thickness to other options such as mineral wool and phenolic foams. The microcell structure of Armaflex materials offers an extremely high water vapour transmission resistance factor (10,000 mu) that not only prevents penetration of moisture from condensation processes, it in turn ensures a long-term thermal insulation performance. The resistance to partial water vapour pressure is also built up through the entire insulation layer meaning no external vapour barrier is required.

For guidance on the thickness of insulation required, BS 5422 is the main standard referred to for specifying insulation materials for mechanical services pipes, tanks, vessels and ductwork.

- No related articles listed