|

Edward Lowton

Editor |

|

| Home> | Energy Management | >HVAC | >Speedy insulation installation |

| Home> | Premises management/maintenance | >HVAC | >Speedy insulation installation |

Speedy insulation installation

27 July 2018

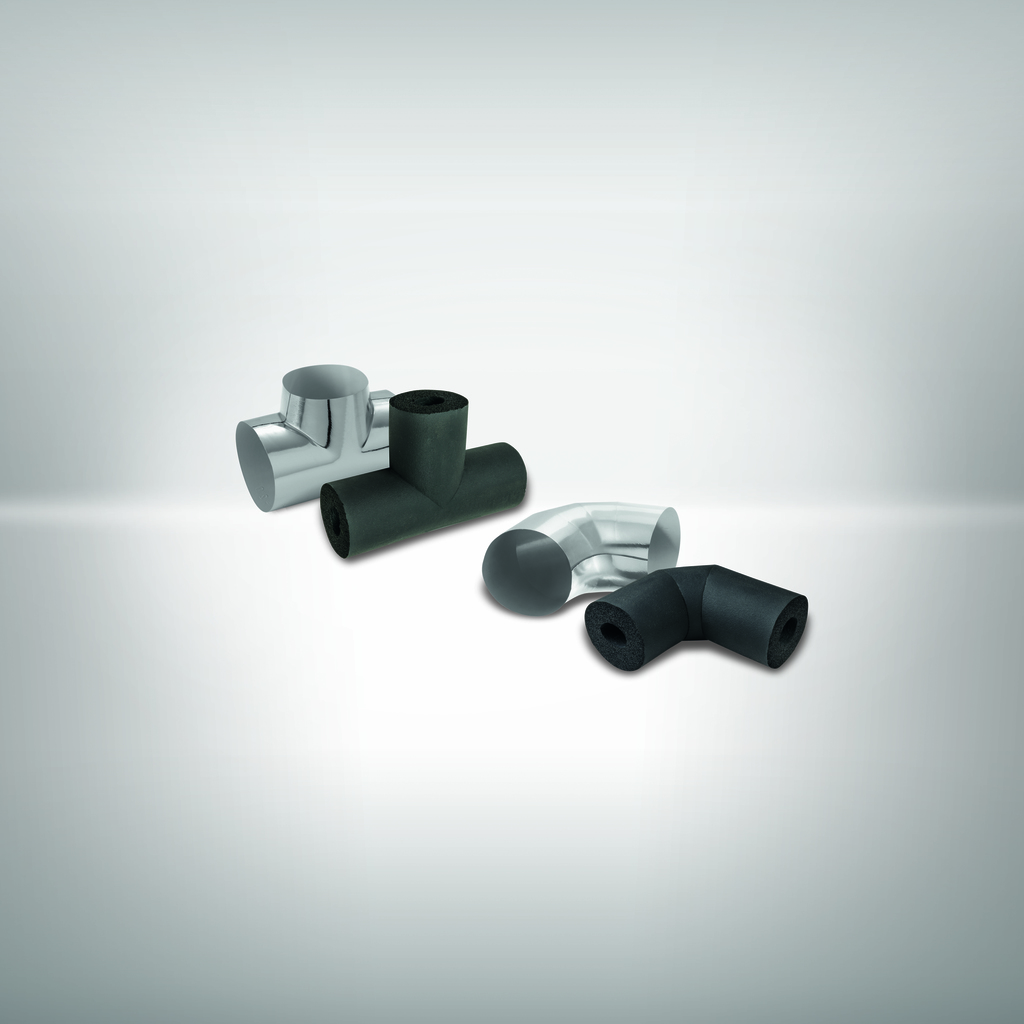

Significant time and cost-savings during installation are two of the benefits claimed by Armacell for its 2-in-1 Arma-Chek Silver insulation system. Now the process has been mades even simpler and faster due to new AF/ArmaFlex elbows and t-pieces.

The prefabricated AF/ArmaFlex elbows and T-pieces are simply cut open, laid around the component to be insulated and glued. Then they are covered with the Arma-Chek Silver elbows and t-piece covering to reduce fabrication and installation times further.

Available are 90° elbows and t-pieces for inner diameters ranging from 15 to 89mm in insulation thicknesses AF-2 (11.5 to 14.5mm), AF-4 (17 to 22mm) and AF-5 (25 to 30.5mm). The fitting covers have engineered wall thicknesses and are coordinated with both the AF/ArmaFlex and the Arma-Chek Silver range. With a thermal conductivity of 0° ≤0.033 W/(m∙K) and a resistance to water-vapour transmission of ≥10,000 the classic insulation material AF/ArmaFlex is said to guarantee that condensation is prevented and energy losses are minimised. The antimicrobial Microban technology provides active protection against harmful bacteria and mould.

Arma-Chek Silver can be installed in one work step. An additional benefit is that the lightweight products can be fitted easily, directly onsite without the need for special tools. They are corrosion-resistant and offer high mechanical stability whilst still retaining a certain degree of flexibility. Arma-Chek Silver is UV-resistant and suitable for equipment located both indoors and outdoors.

A key feature of flexible covering systems is the direct connection to the adjoining insulation, which rules out any risk of water penetrating at these points. If the covering system is not absolutely tight, water can penetrate the insulation. Moisture not only leads to a reduction in the thermal properties of the insulation material, significant corrosion damage can occur underneath the insulation, which can result in renovation work and considerable costs. As the term ‘corrosion under insulation’ (CUI) aptly describes, the processes take place underneath the insulation and its covering, so they often remain undetected for a long time. Flexible coverings also have hygiene benefits: where there are no seams or crimps, no germs can penetrate and settle in the insulation. These easy-to-clean systems are therefore suitable for use in the food industry.

The covering material with a shiny, metal-look surface effectively protects the insulation material against mechanical impact and at the same time is so flexible that it recovers from impact, usually leaving no dents in the surface.