|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Bearings | >Some like it hot: Bearings, lubrication and heat |

| Home> | Efficient Maintenance | >Bearings | >Some like it hot: Bearings, lubrication and heat |

Some like it hot: Bearings, lubrication and heat

26 July 2017

Heat plays a big role in the life of a bearing, being both friend and enemy at different stages of its lifecycle. Phil Burge, marketing and communications manager at SKF, describes how heat can be used as an aid to bearing installation, and looks at its effect on lubricants when the bearing is in service

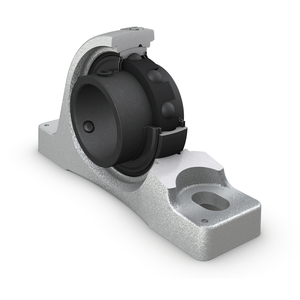

Heat is the inevitable result of friction in rotating machinery and bearings are in the front line where friction is concerned. Their role is to reduce it, thereby minimising internal temperature rises and their unwanted consequences such as lubricant deterioration and premature bearing failure. However, heat has quite a positive role to play at the earliest stages of a bearing's life – installation.

There are various industry-approved methods of mounting bearings and one of them involves the use of heat. Hot-mounting a bearing – by creating a temperature difference between the bearing ring and the shaft or housing - can be achieved using several techniques, some of which are no longer recommended. Traditional techniques such as oil baths, for example, are no longer recommended due to health and safety considerations and environmental problems associated with disposal.

More modern methods include aluminium heating rings, electric hot plates (for small bearings), heating cabinets and infrared radiators. SKF recommends using induction heaters, which quickly apply heat evenly to the bearings. These are safe because the heater and yoke never get hot. As induction heaters cause bearings to be magnetised, they are equipped with a device that automatically demagnetises the bearing prior to mounting.

Before a bearing is placed in service, the operating temperature range of the application should be established to ensure that the correct size/type of bearing and associated lubricant is specified. Bearing temperature should also be monitored regularly (or even continuously) in service, as this will indicate any excursions from the norm, which may denote lubricant problems or damage to the bearing’s raceways. Temperature is therefore a very useful condition monitoring parameter.

Where high operating temperatures are to be expected, either as a result of ambient conditions or generated within the bearing itself, special bearing designs and materials of construction that avoid the heat-induced structural changes that can occur throughout the bearing geometry must be used. SKF has developed a range of both standard and customised high temperature bearings that are capable operating at temperatures as high as 350°C.

Critically, elevated temperatures may also degrade the bearing lubrication, particularly if the wrong type and quantity of lubricant is used, leading to premature bearing failure. Choice and quantity of lubricant, its application and regular inspection are therefore among the most important maintenance functions as far as bearings are concerned.

Above its 'high temperature performance limit', grease degrades chemically, the by-products of oxidation having an irreversible, detrimental effect on the lubricant and consequently bearing performance. Oxidation leads to a chemical reaction producing volatile elements and lacquer formation, which severely degrades the grease’s lubricating properties.

Lubricants, both oil and grease based, are available in many grades and viscosities, and in formulations suitable for use at both high and low extremes of temperature. The temperature rating of the recommended lubricant must be determined at the earliest stage of machine design - dependent upon predicted temperature rises within that machine - and used consistently throughout its operational life.

Temperature monitoring devices are tools that no industrial manufacturing plant should be without. A rapid rise in bearing temperature may be indicative of lubricant deterioration or a sign that the bearing is developing a mechanical fault. So, whether temperature is measured continuously using thermocouples or during regular maintenance checks using a thermal camera, this simple maintenance task is likely to have a significant impact on a bearing’s life expectancy.

- Noise solution

- Fighting old age

- Steeled for success

- Emissions cut

- Mobile app and vibration sensor

- Integrated approach to fan performance

- Rolling bearings in paper machines

- Collaboration agreement to develop use of active magnetic bearing applications

- Shaft alignment tool

- Correct lubricants: Key to performance