|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Training | >Reducing the risk of human error in manual tasks |

Reducing the risk of human error in manual tasks

22 August 2017

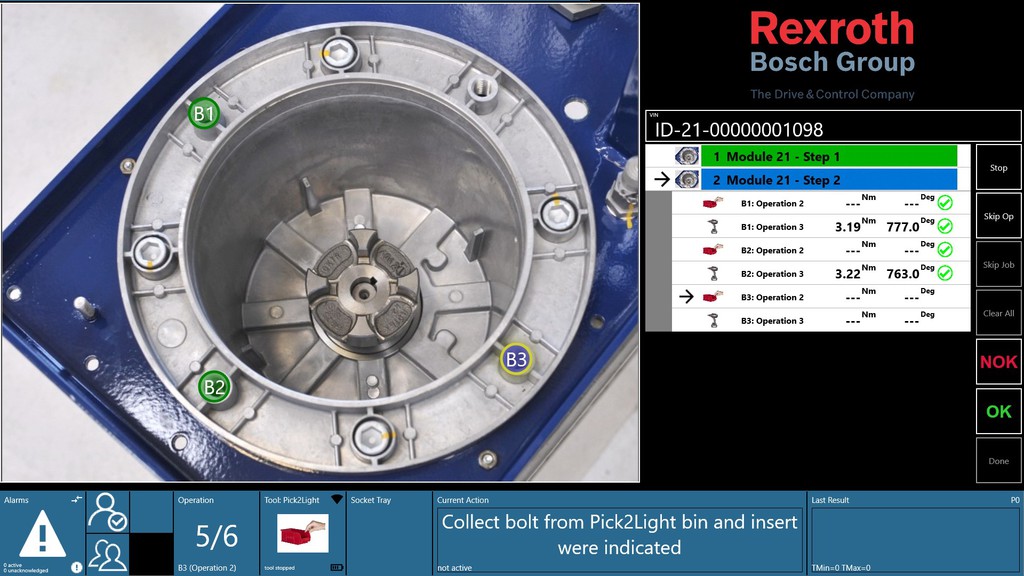

One of the main issues associated with manual assembly processes is human error – with its potentially costly ramifications. To tackle the issue, Bosch Rexroth has developed a step-by-step virtual guidance system to support workers in a production environment.

The new Operator Guidance System (OGS) helps optimise quality and traceability, while simplifying the task for users.

Following initial set-up, OGS provides on-screen, step-by-step instructions ensuring the correct components and tools are used for each process. This eliminates the risk of incorrect part fitting or tool selection, reducing rework time, potential damage and delays in production.

Designed from the start to be a low cost solution, OGS is a Windows 10 application that can function on an entry level PC. Every process is recorded by the system, helping issues to be addressed immediately. Similarly, once a job is complete, results are automatically saved, creating a clear audit trail. In turn this data can be used for end of line buy off, product re-work and long term traceability.

Stuart Williams, emerging technologies manager at Bosch Rexroth, says: “Complex manual production lines can be subject to human error as they often rely on an ‘expert’ worker who knows the process for a particular operation. This often leads to an uncontrolled process that can't be audited, coupled with a complete lack of flexibility when redeploying workers with changing production targets.

“OGS will transform the way manual assembly lines operate for the better. It will make human error almost impossible and optimise quality and traceability. Crucially, by using OGS, manufacturers can maintain reputations and keep costs down. The time and resources to train workers is also reduced, as there is always a clear picture and instruction on what to do next.”

- Manufacturers must do more to tackle poor ergonomic design

- Safe measurement, indication and control of rotational speed

- Inside intelligence helps boost maintenance

- Interactive communication platform

- Industry 4.0 ready guidance platform

- Maintenance in the digital world

- British manufacturing 'welded to traditional techniques'

- Oil contamination: Report available

- Maintenance: an eye opener

- Hydraulic equipment maintenance & improvement