|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Training | >Budgets identified as major barrier to training |

Budgets identified as major barrier to training

28 January 2018

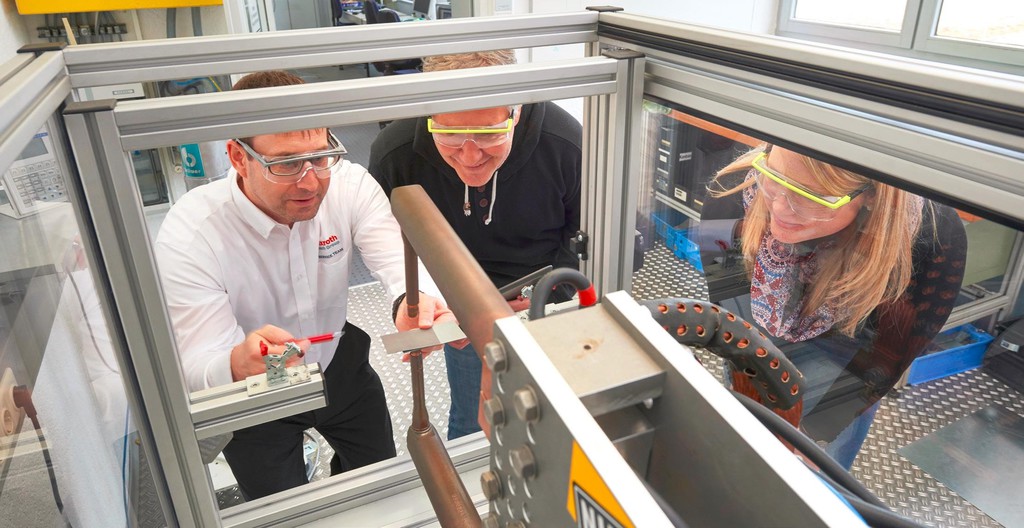

A survey commissioned by Bosch Rexroth highlights the correlation between training adoption and budget, and the impact this is having on implementation of Industry 4.0.

The report: ‘Tackling the training gap in UK manufacturing’ discovers that 43% of engineers identify budget constraints as one of the key barriers to adopting a more rigorous training plan. The study revealed that, in a quarter of companies, less than 10h of training is delivered to employees each year on average, and more than half of respondents anticipate training budgets will stagnate in their organisation over the next five years, and

In the UK, ‘automation’ is an area which is dramatically increasing, however productivity – measured both by output per worker and per hour worked – is significantly lower against the UK’s major trading partners in Europe and the US. For this reason, it is worrying to discover that automated production processes and modern automation techniques were identified in the report as areas where the greatest gaps in knowledge exist.

“As the UK manufacturing sector borders on the cusp of Industry 4.0 with increased automation, businesses must update their approach to training” says Richard Chamberlain, service product manager at Bosch Rexroth. “We must upskill the workforce and empower engineers with the skills they need to use Industry 4.0 technologies, whilst offering continuous development opportunities to individuals is vital.

“At face value, the survey shows that the majority of organisations are committed to training, with only a tiny proportion (2%) of organisations admit to providing no training at all. However, it appears, in many instances, to be piecemeal and an activity which is squeezed in around day-to-day operational requirements. Rather than being seen as a core value-adding function which requires strategic investment of time, resources and of course, budget.

“What is also clear is that there was no widespread optimism around a greater commitment to, and role for, training in the next five years.

“We are constantly reminded that Industry 4.0 will transform manufacturing for the better – with the promise of improving efficiency and productivity. Yet if our engineers are unprepared for the introduction of new automated technologies this will inevitably stall the progression towards Industry 4.0. Therefore in order to remain competitive, training should be one of the first priorities in order to help employees adapt to meet the rapidly changing manufacturing processes.”

To download the white paper, please visit: http://bit.ly/RexrothTrainingWP

- Inside intelligence helps boost maintenance

- Offshore developments

- White paper on hydraulic filtration media

- Manufacturers must do more to tackle poor ergonomic design

- Online hydraulics catalogue

- Hydraulic equipment maintenance & improvement

- Internet of Things innovators recognised

- Oil contamination: New report available

- Interactive communication platform

- Prepare for new directive