|

Edward Lowton

Editor |

|

BIM technology assists in the cleanroom installation

02 October 2017

Connect 2 Cleanrooms has completed the installation of a Monobloc panel system for global medical products and technologies company, ConvaTec to assist with the manufacture of wound dressings.

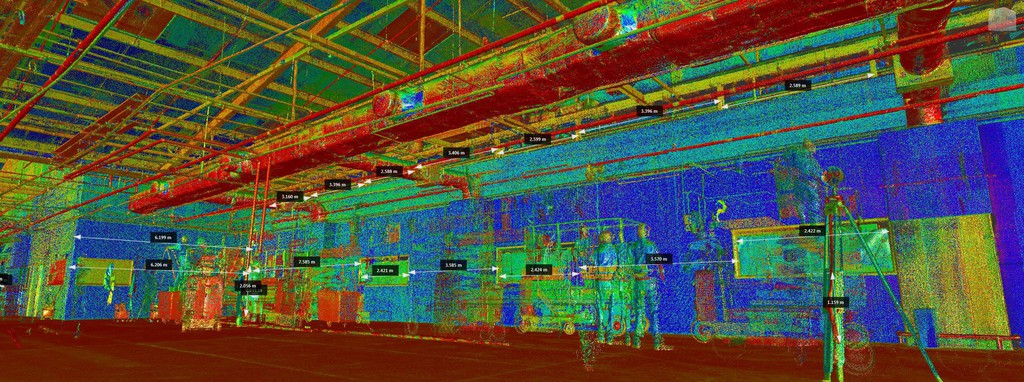

To ensure an accurate cleanroom design, aligned with the existing facility, the use of Building Information Modelling (BIM) techniques assisted the design stage for Connect 2 Cleanrooms. Point Cloud 3D design software is said to allow for a more accurate design, shorter lead times and a more cost effective solution.

Spanning 951m² and achieving ISO class 8, the cleanroom has a separate change and material transfer area. The main cleanroom area houses a stitch bonding processes and has a footfall of 990m², achieving 21 air changes per hour. Monitored via Connect 2 Cleanrooms' ECO cleanroom control system with temperature and humidity control, the cleanroom features HEPA filtration, accessible externally for non-disruptive maintenance.

A bespoke touch screen control system was installed to continually log all these data parameters, which integrates with ConvaTec’s current BMS. The integrated alarm signals when these parameters vary beyond a specific threshold such as pressure differential and temperature & humidity.

The design incorporates high speed and hinged interlocking doors between transfer and change areas to aid the flow of materials and personnel.

- Modular cleanrooms

- Connect 2 Cleanrooms offers services for ventilator production drive

- Cleanroom timescale reduction

- Modular clean room solution

- Stable manufacturing environment

- Clean air solutions

- Double award winners

- Supporting the automotive sector

- Modular cleanrooms

- Cleanroomshop website relaunch