|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Labelling, marking and barcoding | >Dry inks at high speed |

Dry inks at high speed

02 December 2013

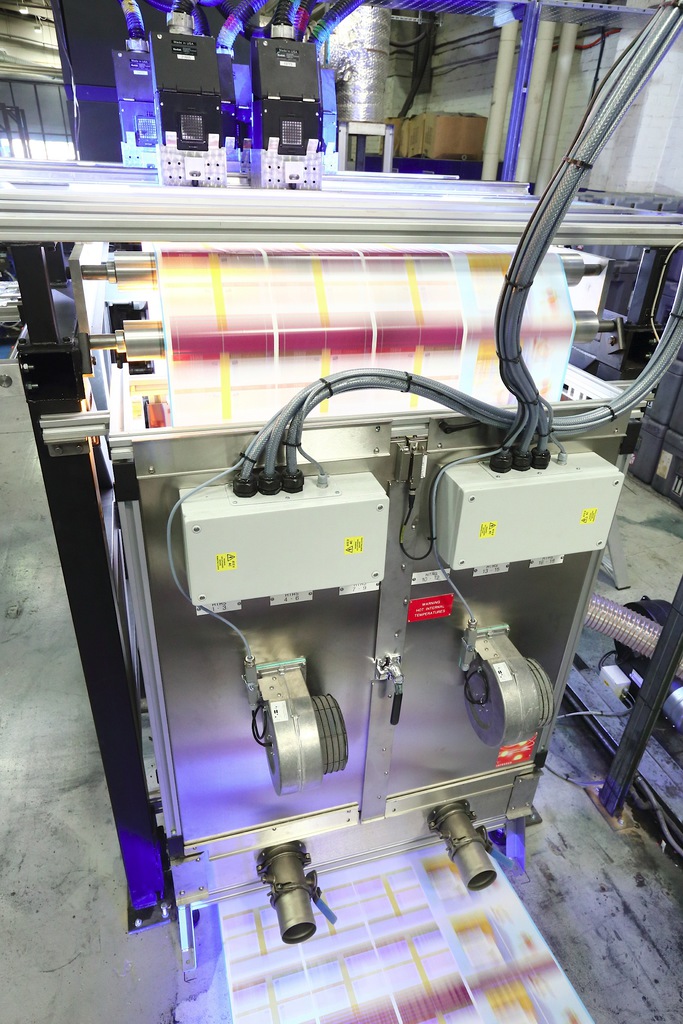

An investment of £180,000 in Carbon infra-red (CIR) emitters from Heraeus Noblelight have allowed communications company GI Solutions to achieve the rapid drying of water-based inks at line speeds of up to 1000 ft/min (300m/min) on printing machines at their Leicester factory.

Heraeus' Ian Bartley says: "The Versa Mark inks used by GI Solutions are water-based and water molecules most readily absorb IR energy when it is radiated in wavelengths between 2 and 4 microns and CIR has a peak wavelength of 2 micron and radiates most of its energy in the 2 to 4 micron range.”

Since installing the system, energy costs have been substantially reduced because of the efficiency of CIR in removing water. GI Solutions' Ifor Pedley adds: "As the ink is now dried before it has a chance to be absorbed by the paper, quality in terms of sharpness of image has been improved."

- Electric and gas infrared solutions

- Efficient gelling

- IR heating in quality role

- Infrared suitability tested

- Lab relocates to Cambridge

- Gas catalytic ovens prove themselves fit for purpose

- Infrared system used in board coating

- Air rinsing for jam pots

- Chocolate moulds get pre-heat treat

- Heating systems on show