|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Motors and drives | >Modular drum motors |

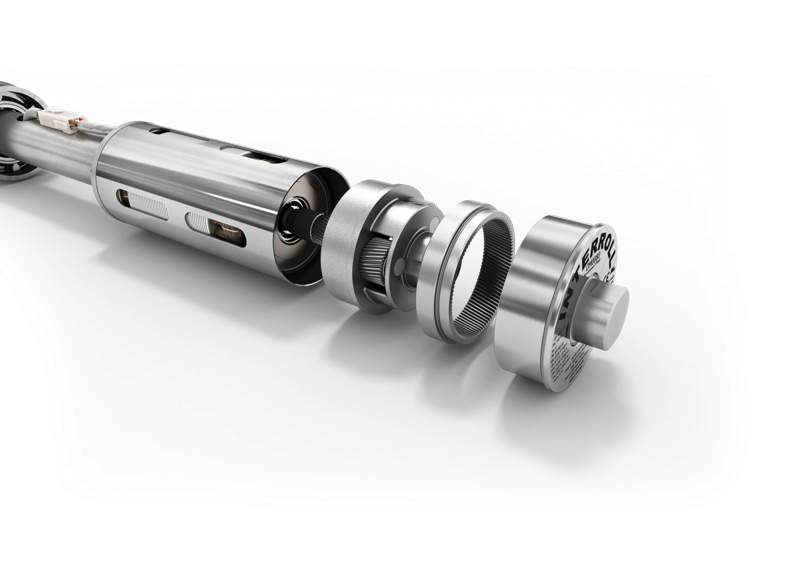

Modular drum motors

26 May 2018

Interroll’s new motor platform offers a completely modular design, encompassing both synchronous and asynchronous technologies. Available first in 80mm-diameter drums with plans to expand to the entire Interroll range.

The platform makes it easy to combine all components and is said to guarantee short and reliable delivery times. Options such as encoders, brakes and return stops make it easier for system integrators and OEM’s to plan and implement efficient materials-handling solutions. The motors are IP69K protected and can be quickly cleaned, especially compared to gear-motors.

Featuring stronger shafts and ball bearings, this guarantees a long service life, while robust planetary gears make it possible to transfer high levels of torque to conveyor belts efficiently and quietly. An expanded number of gear stages provides a greater speed range, making it easier to design conveyor systems that achieve throughput requirements precisely.

There is an option for a simple plug-in connection, reducing downtime for maintenance and repair work, resulting in considerable cost advantages for the user.

- Modular conveyor platform

- Showing dynamic storage solutions

- Motorised drive solutions

- Interroll expands belt curve offering

- Tapered elements secured from inside

- Carton wheel flow beds designed for simple installation

- Energy efficient drive

- Advances in automated conveyor technology

- Interroll Ltd becomes latest AMHSA member

- Speed controller for gravity roller conveyors