|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Conveyors | >Products for use in refrigeration applications |

Products for use in refrigeration applications

05 October 2015

Logistics solutions must be designed to suit different conditions and temperature ranges as low as -30°C in deep-freeze areas. This also applies to conveyor rollers.

Materials shrink differently at very low temperatures, such as metal tube and techno polymer parts contained in a conveyor roller. In critical cases, such as unfavorable tolerance pairings with pure press fit connections, the drive head can rotate inside the tube. In such cases, driven conveyor rollers will be rendered useless.

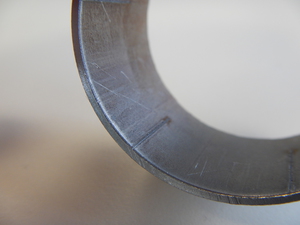

To ensure failsafe security in operation, Interroll deep-freeze conveyor rollers are not only flanged at the tube, but equipped with a metal star-shaped fitting to provide a positive grip and secure the roller endcap. The extremely sharp spikes of the star furrow into the tube interior to firmly connect the roller endcap on insertion and there are no protruding external edges that could damage packages being conveyed.

Comprehensive application and recurring dynamic load testing in deep-freeze environments has proven Interroll product quality.

Interroll products, such as motorised rollers or conveyor rollers, are designed and proven, which can save a lot of money by avoiding maintenance and component replacement time.

Compatible components are essential to every plant and conveyor system to ensure optimum functionality. For this reason, Interroll offers a product package for zero pressure accumulation (ZPA) roller conveyors. Power supplies, cables, control boards, sensors, conveyor rollers, motor rollers, drive belts & O-rings and assembly tools are designed for use under deep-frozen conditions.

Drives influence energy consumption when they transport products. The energy costs in a cold storage area can account for up to 25% of the overall operating costs. Interroll says that with its 24V RollerDrive, energy consumption can be reduced by about 50% compared with conventional 400V technology at medium throughput volumes of 600-1000 containers per hour.