|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Conveyors | >New profile for driving belts |

New profile for driving belts

16 July 2014

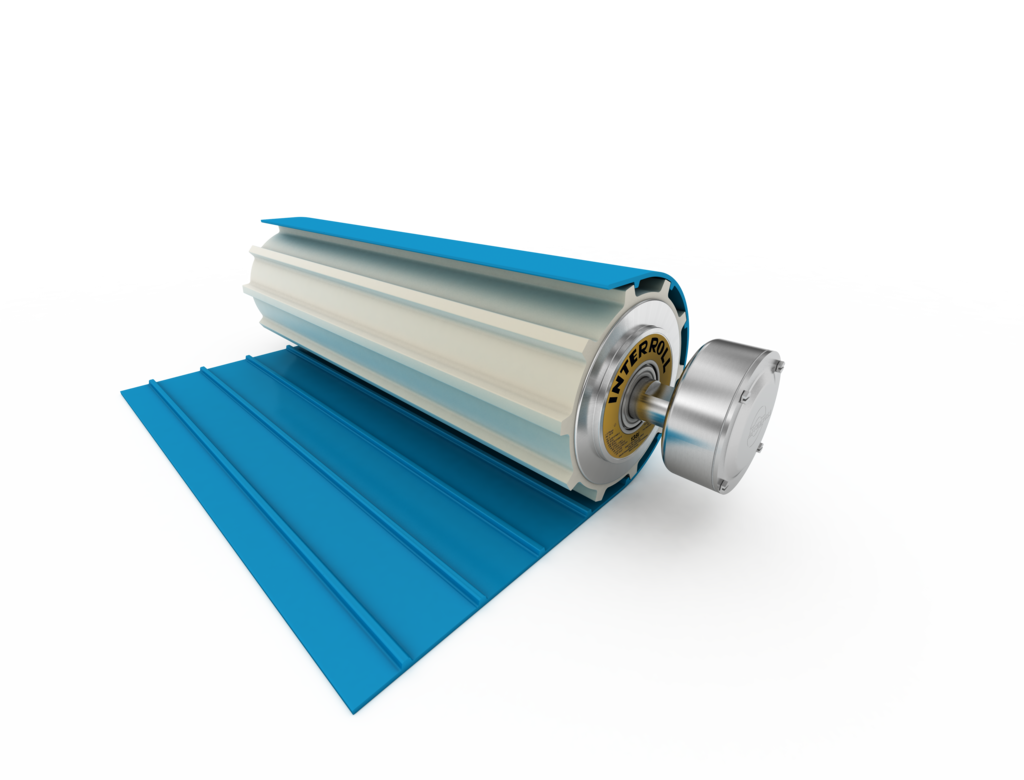

Interroll has developed the Interroll Multiprofile, a new profile for its asynchronous drum motors and synchronous drum motors that feature frequency converters, which can be used to drive various conveyor belts from different manufacturers using only one Interroll Premium Hygienic PU Profile.

This translates into a high degree of flexibility for customers because they can replace belts without having to replace the drum motor. This reduces the time needed to retrofit and perform maintenance work on the conveyors quite significantly. Furthermore, Interroll’s Multiprofile contributes to lower storage and thus saves customers money and storage space.

The Interroll Multiprofile is manufactured using the 'Interroll Premium Hygienic PU' which is also a new development. This hygiene-friendly material complements the Interroll product line that meets EHEDG guidelines. The new material for rubber coating drum motors is well suited for positively driven belts and has a smooth surface that prevents bacteria from forming on the material.

Interroll says that, in addition to a low noise level and high resistance to oil, grease and chemicals, the Interroll Premium Hygienic PU stands out due to its lower friction.

- Products for use in refrigeration applications

- Interroll intensifies exchange of expertise with digital channels

- Powerful synchronous drum motor

- On show in Dublin

- Motorised drive solutions

- Dynamic flow store

- Interroll establishes new service organisation

- Modular drum motors

- Conveyor solutions for chilled and deep-freeze environments

- Showing solutions to store and convey efficiently