|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Motors and drives | >Variable speed drives: Ready-to-go energy savers |

Variable speed drives: Ready-to-go energy savers

14 November 2022

With energy efficiency more relevant than ever, variable speed drives have an important role to play in providing energy savings, says Marie Hammer

WHEN TALKING about green transition many people think of renewables. Wind and solar farms come to mind. While renewables are without doubt part of the green transition, energy efficiency is often overlooked. However, energy efficiency enables us to run at the speed required to limit global warming to 1.5 degrees.

The climate crisis is reason enough to focus on energy efficiency. According to the International Energy Agency (IEA) more than 40% of reductions in CO2 emissions this decade must come from improvements in energy efficiency. Combined with high energy prices and energy security issues, energy efficiency is more relevant than ever.

It should be clear to everyone why energy efficiency is key. The next question is how? Do we have the solutions at hand to ramp up energy efficiency? The short answer is yes, we do.

Improving energy efficiency

We have the solutions to improve energy efficiency - everywhere and today. In transportation, construction machinery, energy systems, homes, and industries. And they are cost-effective solutions with short payback times. While the green transition needs new and not yet developed solutions, it is urgent we translate today's technologies into concrete energy savings now.

To take a solid example: variable speed drives (VSDs). Currently, there are about eight billion electric motors in use in the EU consuming nearly 50% of the electricity produced in the Union. These motors are industry workhorses. Pumps moving fluids, fans moving air, compressors, conveyors – every machine using rotational force to do its job.

These pumps, fans and compressors often run at constant speeds. Flow is controlled by manually opening and closing valves. Fans run at constant speeds and vents control the flow rate of air delivered to a building. But the fan motor continues working at full speed, using electrical energy at the full-load rate, even when demands are low. This is extremely inefficient.

Energy saving with VSDs

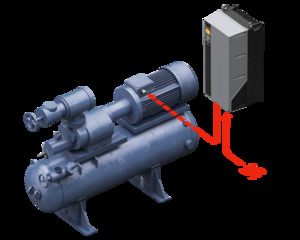

The good news is there is more energy efficient alternative: using a VSD. A variable speed drive sits between the electrical supply and the motor. It controls the speed of an electrical motor by changing the frequency and voltage of power it supplies. Power is fed to the drive, which regulates the power fed to the motor.

In the fan example, the VSD controls the fan speed in response to the demand. When the demand decreases, the flow rate is reduced by slowing the fan, effectively reducing the energy used.

The result: instant energy savings. Using a VSD to control power supply to electric motors can typically save 15-40% of energy consumed. That’s significant, especially when production plants often have several hundred electrical motors that could use a VSD. It also minimises the stress on mechanical equipment during start-up and operation, increasing the motor’s lifetime.

Furthermore, the investment case is convincing, with a payback time typically under two years. According to the IEA, one dollar invested in energy savings will give you three dollars in energy savings over the lifetime of the equipment. For electric motor-driven systems, it's one to seven. As this analysis is from 2018, one can only imagine the investment payback now with soaring energy prices.

Thanks to technologies such as variable speed drives, it is possible to achieve significant energy savings, save money on energy bills, and save CO2 immediately.

So, for decision makers - in the public and private sectors - the message is clear. We need to kick-start much needed energy savings and prioritise the quick wins such as VSDs.

Marie Hammer is director of industry affairs at Danfoss Drives

For more information:

Tel: 0330 8086 888