|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Condition monitoring | >Time to embrace change |

| Home> | Plant, Process & Control | >Industry 4.0 | >Time to embrace change |

| Home> | Energy Management | >Motors and drives | >Time to embrace change |

Time to embrace change

25 March 2019

When new technology emerges, there’s a distinct split between digital innovators who want to implement it first, and those who prefer tried-and-tested methods, comments electric motor repair specialist, Houghton International.

Establishing electricity as a commodity

The advent of electricity is a major technological milestone that has fuelled today’s technological advances.

In London and Manhattan, Thomas Edison built stations to generate electricity in 1881. 12 months later and electricity was available as a commodity, changing industry forever.

Factories of the time relied on steam power, driving their operations with large, cumbersome and often dangerous machinery. Once electricity was made available, this could have all changed — but it didn’t.

Even though electricity was available, by 1900, less than 5% of factories made use of electric motor power. Many preferred to rely on steam power as they were uncomfortable with the level of change brought about by the introduction of electric motors. It would trigger a revolution in thinking that many simply didn’t want to consider.

The change brought about through the installation of electric motors would be disruptive, putting off many factory owners. Production could take place following logic, rather than the direction of the driveshaft. Factories became safer and cleaner too, while the staff themselves began to set the pace.

To implement the motors, the entire infrastructure of the factory had to be altered. And with time, it did — as change always does. By the 1920s, manufacturing productivity had increased significantly, as factory owners increasingly implemented electric motors.

Given the 40 years between electricity commoditisation and the booming manufacturing rates of the 1920s, we can assume that new technology does not automatically deliver instant results. Rather, we can only reap the benefits when we fully understand how best to use it.

In today’s terms

We’re still facing a traditional vs. technological battle today, almost 100 years later. Take electric motors themselves, for example. While they have been fully adopted into many applications, business owners are still facing decisions on whether to upgrade their model to one that promises further efficiencies.

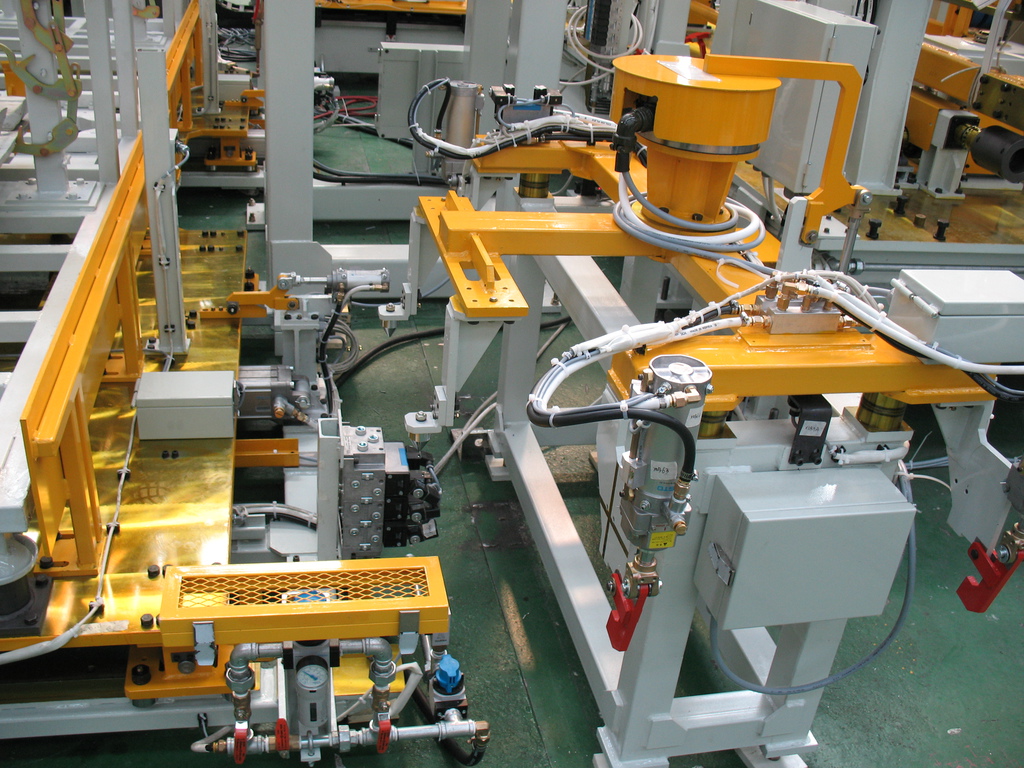

While supporting the development of a number of sectors and improving efficiency, Industry 4.0 is making the traditional-technological disparity even clearer. Dubbed the fourth industrial revolution, Industry 4.0 is transforming industries through automation and real-time data. One example of this is condition monitoring, the process of using technology to monitor the state of machinery to detect significant change and therefore problems.

Involving techniques like vibration and lubricant analysis as well as acoustic emissions, condition monitoring is part of predictive maintenance. For those who have enabled Industry 4.0, they are already at an advantage, as they are able to anticipate when maintenance work will be required, in turn reducing the impact unplanned downtime can have. Those who are unaware of the potential of Industry 4.0 are unable to access this level of insight, putting them at an automatic disadvantage.

How will new technology benefit me?

The development and release of new technology shows no signs of slowing, so what advice can businesses benefit from?

Weigh up in full the benefits of your potential technological investment and where it will operate within your business. Consider the amount of work that is required for implementation and whether this and the associated costs are justified by what you’ll gain. If in doubt, enlist the help of a professional to advise you on the right solution.

Regardless of the scale of the change you’re making, technology remains critical to how businesses across all sectors operate. Shying away from digital advancements is no longer an option; choose to be an innovator or delay the implementation of these new developments. Either way, change is happening now — and you can’t afford to stand still.