|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Power transmission | >Curved-tooth Nylon sleeve gear couplings |

Curved-tooth Nylon sleeve gear couplings

07 February 2019

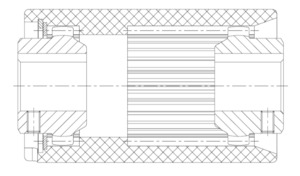

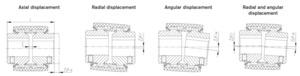

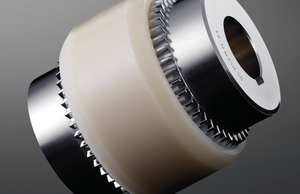

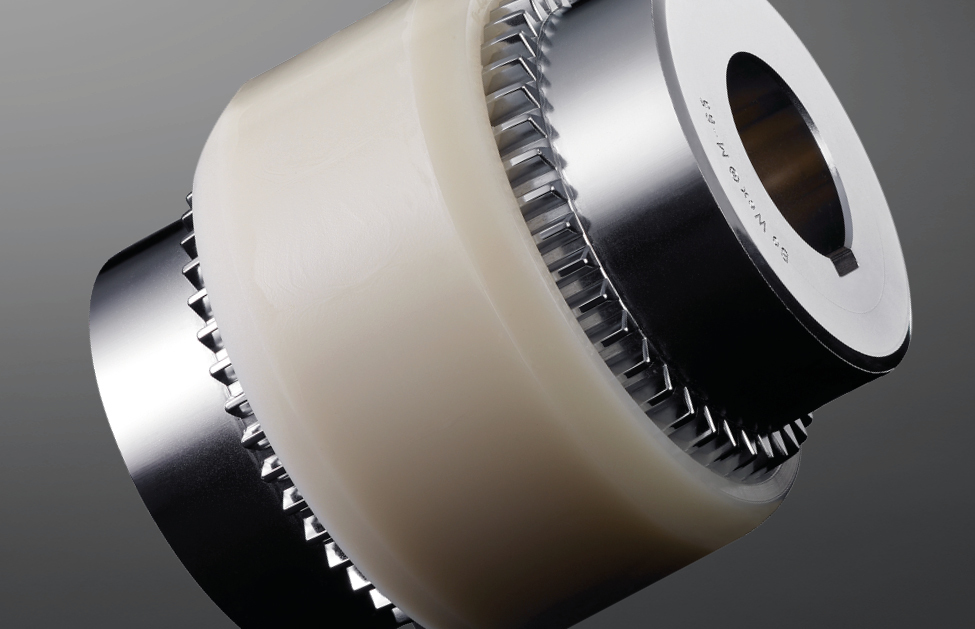

BoWex curved-tooth gear couplings are flexible shaft connections for positive torque transmission designed to compensate for axial, radial, and angular shaft misalignment. KTR’s BoWex M, consists of two toothed hubs and a nylon sleeve with toothing inside.

KTR says that, while a standard jaw-type coupling might provide an advantage in its ability to adjust the performance of the coupling by changing the shore hardness of the elastomer insert – not possible with a nylon sleeve gear coupling – the BoWex M also offers advantages.

A standard BoWex M coupling is double cardanic. This means the design features two points of flexion, offering significant compensation for radial misalignments. Both radial and angular misalignment is combated by the operating principle of the crowned gear tooth. In contrast to straight gear designs, KTR comments that crowned gears are an effective answer to edge loading problems caused by excess misalignment and deflection.

By using hubs with crowned teeth, in combination with the smooth and hard wearing surface of the polyamide sleeve (crystalline structure), the BoWex M offers a maintenance free operation. The specially crafted nylon sleeve also offer additional benefits such as high thermal stability and resistance to lubricants and other chemical solutions. The coupling also has the ability to operate without lubrication or risk of corrosion due to the nylon and steel material components.

Furthermore, the nylon sleeve and hub combination enables a useful amount of axial misalignment, as hubs can advance and retract within the spline teeth of the sleeve itself. In fact, some applications may require sleeve designs with elongated splines in order to increase the permissible amount of axial movement.

BoWex M-C couplings under size 80 come with the of a non-electroconductive nylon sleeve (PA-CF) made from carbon fiber strengthened polyamide. This makes the model suitable for power transmission drives in hazardous areas as they are considered antistatic with protection against friction and shock sparks

Coupling selection

The BoWex M is suitable for both mobile and stationary compressors, and vacuum pumps. However, depending on the specific application, a variation may be required.

In order to select the proper coupling size, you must know the required shaft or bore sizes of your operating system. You will also need to note the necessary power and speed of your application, as different applications may require slightly different models. Lastly, taking the example of a vacuum pump, you will need to measure the distance between shaft ends (DBSE). Incorrectly measured DBSEs can result in an incorrect engagement of the coupling hubs and sleeve, so it may also be necessary to take into consideration the ambient and operating temperatures of your application and the effect expansion and retraction can have on your shaft lengths.

KTR adds that BoWex M is a coupling specifically designed to combat a problem that accounts for nearly 50% of damage to rotating equipment – misalignment. It is important to keep in mind however, that although the BoWex M is able to handle misalignment, it remains critical to operate within the allowed tolerances in order to prevent failures and damage to your system.