|

Edward Lowton

Editor |

|

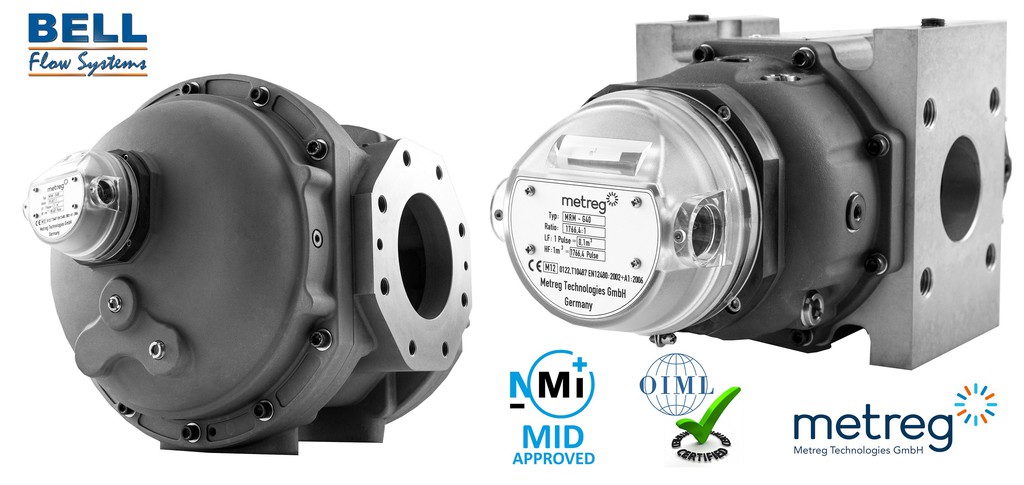

Rotary displacement gas meters MID and OIML approved

10 October 2019

MRM turbine gas flow meters are now available in the UK from Bell Flow Systems. They are manufactured by Metreg Technologies which offers a product range for fiscal and non-fiscal gas flow measurement for industrial and commercial applications.

The MRM rotary displacement gas flow meter is designed for fiscal metering of natural gas and is approved according to the European requirements of EN12480, MID (2004/22/EG) and OIML R137-1 & 2: 2012.

The MRM rotary displacement gas meter is suitable for installation in hazardous areas – Category 2 (Zone 1) II 2 G c IIC T4 X. It is suitable for the following gases: Natural gas, town gas, propane, butane, ethylene, air, nitrogen, with further gases on request.

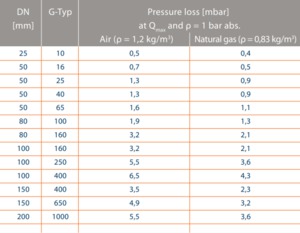

Rotary gas meters are characterised by their very compact design and high accuracy. The MRM rotary meter requires no inlet or outlet straight pipe lengths or flow conditioning and is insensitive to severe gas flow fluctuations (discontinuous operation). The rotary meters MRM are manufactured with large measurement ranges due to the precision machining of the parts and a very reproducible assembly process. The standard calibrated measurement range for the MRM is 1:50. Extended measurement ranges to 1:200 are optionally available according to approved and certified measurement ranges.

The MRM rotary gas meters show very stable and reproducible measurement results. The design of the housings and pressure containing parts has been optimised especially for outstanding operation, even under challenging torsional and bending stresses. The meters can withstand more than twice the specified torsional and bending stresses after installation as defined in EN 12480.

The lifetime durability of the MRM rotary gas meter is very stable due to the large dimensioned high precision ball bearings, made in Germany, along with the high precision machining of the body and all moving parts. After machining all aluminium parts are hard anodised for reduced friction and higher resistance to mechanical wear and tear or chemical attack. Utilising the LF of HF pulser (reed contact) the volume pulse output sensors allow for remote monitoring, data recording and linking with Building Management Systems (BMS) as well as with gas volume correctors (EVCs) and the company's ATEX telemetry systems.

- No related articles listed