|

Edward Lowton

Editor |

|

Process Air Heaters

23 March 2021

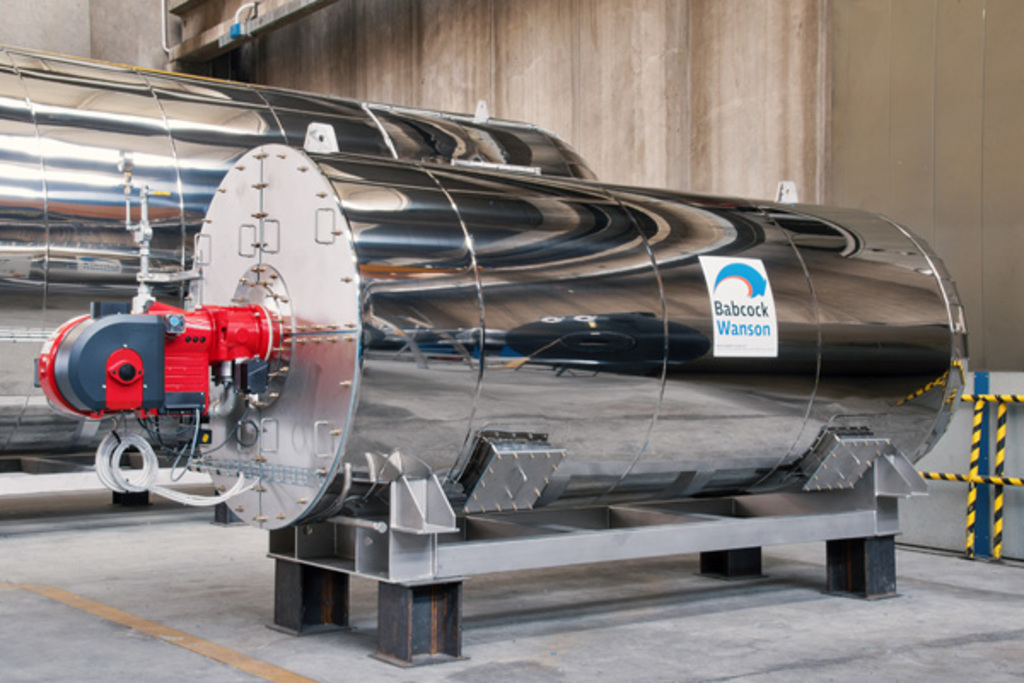

Babcock Wanson has been designing and manufacturing both Direct and Indirect Process Air Heaters for industrial drying applications for many decades.

Process Air Heaters are used in a wide range of industrial processes, including curing, drying, heat treating and shrinking, sterilising, bonding and chemical processing. The heaters are designed to work within a range of airflows and air pressures, with a large variation of discharge temperatures.

Industrial Air Heaters fall into two groups: Direct and Indirect. As the name implies, Direct Air Heaters have direct contact between the products of combustion and the process air stream. Indirect Air Heaters are designed to prevent the process air from coming into contact with the products of combustion.

The key to the success of an industrial Air Heater is to make sure it is designed to meet the process need and will provide longevity, durability and robustness, rapid response time and efficient heat transfer.

- No related articles listed