|

Edward Lowton

Editor |

|

| Home> | Handbooks | >Maintenance Management Guide | >Helping the wind industry solve a critical maintenance issue |

Helping the wind industry solve a critical maintenance issue

11 May 2023

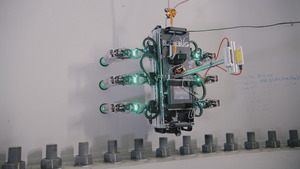

IN A first of its kind demonstration, a six-legged robot has shown how it can inspect wind turbine bolts autonomously, eliminating the need for technicians to loosen and retighten thousands of bolts per wind turbine as part of routine maintenance.

Funded by Innovate UK and executed in collaboration with GE Renewable Energy and the Offshore Renewable Energy (ORE) Catapult, the project brought together BladeBUG and EchoBolt, both fast-growing UK SMEs with their own separate, well-established technologies.

The cost savings to the European onshore and offshore wind fleet could exceed £250m per year, according to ORE Catapult.

"The challenge of regularly retightening thousands of wind turbine bolts, that can weigh up to 20kg each, is the leading cause of scheduled downtime in the wind industry, and presents a number of significant health and safety challenges to operators," said Pete Andrews, Echobolt's founder. "EchoBolt technology is actively supporting over 4GW of capacity in managing bolted joints through a condition-based approach, eliminating the requirement for time-based retightening.

"However, we are determined not to stand still and are passionate about remaining at the forefront of innovation in the sector. The opportunity to collaborate on the development of EchoBoltBUG has provided a fantastic demonstration of the pathway to an autonomous future for the wind industry," he added.

It will also reduce time spent on maintenance, critical structural failures and extend turbine lifetimes at sea, all of which will be crucial as the European market looks set to accelerate its expansion as Russian fossil fuel imports reduce.

"The demonstration proved the EchoBoltBUG is not only capable of performing a bolt check for any loss of tension, but doing it in a much more autonomous way," explained Chris Cieslak, founder of BladeBUG. "The idea of the robot independently checking a set of bolts, without assistance, is now a reality and takes maintenance of wind turbines to the next level by making them safer and more cost-effective for operators."

The robot successfully crawled the interior of ORE Catapult’s 7MW Levenmouth Demonstration Turbine in Fife, inspecting bolts to identify any loss of tension. The achievement could lead to the production of a predictive schedule for future operations, while also paving the way for the EchoBoltBUG to perform bolt checks autonomously.

"BladeBUG and EchoBolt are companies that came to us at the very start of their journeys and already had made spectacular innovative progress when they decided to team up on a new solution," stated Andrew Macdonald, ORE Catapult's director of offshore wind development and operations. "Their separate technologies have completed multiple successful trials at our National Renewable Energy Centre in Blyth and on our Levenmouth Demonstration Turbine. EchoBolt also tested its handheld ultrasonic inspection device on GE Renewable Energy’s Haliade-X turbine when it was undergoing trials with us.

"This collaboration provides them with an additional product to add to an impressive list of solutions. It also proves that a single platform, like BladeBUG, can go on to fulfil a wide variety of functions at a wind farm. This greatly strengthens the value of investment in robotic technologies and their offering to the market.

“The companies have enormous interest from the sector for their solutions. The contract wins and growth of their workforces attest to a spectacular British innovation story that will have multi-million-pound export value in the coming years"

- The hidden costs of poor cleaning practices in industrial settings

- Keeping track of critical alarms during a pandemic

- Reducing energy costs for manufacturers

- Pick and weld automated preforming

- Why a HAYLEY DEXIS onsite team member is worth their weight in gold

- Collaboration allows CME to offer a complete packaging solution

- Proven HBK Force Measurement Technology goes digital with IO-Link

- Industrial LiDAR installations will outpace automotive

- Vertiv launches new Power Swap programme in the UK

- Bombardier wins trains contract

- Healthy trucks, healthy site

- The Sound of Silence: Communicating with machines

- Inspection, test & monitoring: A choice of career development pathways

- Compressor efficiency: Specification matters

- Raising issues of concern

- Mattei explains why compressor maintenance is essential

- Maintec 2013: Innovation galore

- Co-Locations for Maintec 2014

- Maintaining strategies for success

- Considerations for machine tool maintenance