|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Sensors and instrumentation | >Hot runner balancing act |

ARTICLE

Hot runner balancing act

25 January 2013

The CoMo Injection system from Kistler Instruments uses cavity pressure to monitor and control the injection process. The system has now been extended with the addition of the MultiFlow option to provide automatic hot r

The CoMo Injection system from

Kistler Instruments uses cavity

pressure to monitor and control the

injection process. The system has

now been extended with the addition

of the MultiFlow option to provide

automatic hot runner balancing

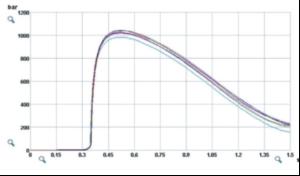

Cycle by cycle, CoMo Injection

with MultiFlow monitors the

pressure profile of each cavity of a

hot-runner mould from injection,

through compression and holding, to

the cooling phase. During the

injection and holding pressure

phases, the software analyses the

pressures curves in all cavities. The

system automatically calculates the

optimal set-point temperature for

each hot runner tip, which is then

transferred via an interface to the hot

runner controller. The mould is

automatically balanced during

process start-up, and continuous

optimisation keeps it stable during

production. The CoMo Injection

continuously monitors the quality of

parts produced and signals any need

for automatic separation of rejects.

Hot-runner balancing eliminates the need for time-consuming manual optimisation and adjustment.

Hot-runner balancing eliminates the need for time-consuming manual optimisation and adjustment.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION