|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Sensors and instrumentation | >Making sense of new technology |

ARTICLE

Making sense of new technology

25 January 2013

With any displacement measurement application, there is a trade-off between the benefits and limitations of a particular technology.Here, Micro-Epsilon compares four types of non-contact displacement measurement technolog

With any displacement measurement application, there is a

trade-off between the benefits and limitations of a

particular technology.Here, Micro-Epsilon compares four

types of non-contact displacement measurement

technologies, looking at the pros and cons of each

The use of non-contact displacement technologies in precision measurement is growing rapidly.

Customers need to measure more accurately, to sub-micron or nanometre resolutions, and against difficult surfaces or materials that cannot be touched during measurements.

These materials include silicon, glass, plastics, miniature electronic and medical components, and food-based surfaces.

This growth has prompted development of new technologies and the adaptation of existing technologies to meet these new measurement requirements and to improve measurement accuracy and resolution. Noncontact displacement sensors come in a wide variety of shapes, sizes and measurement principles. As well as eddy current and laser triangulation sensors, capacitive and confocal sensors are now popular, so it is critical that engineers have a greater understanding of the strengths and limitations of each principle when selecting one for an application.

Eddy Current Principle The eddy current measurement principle is an inductive measuring method. A coil is supplied with an alternating current, which causes a magnetic field to form around the coil. If an electrically conducting object is placed in this magnetic field, eddy currents are induced, which form an electromagnetic field according to Faraday's Induction Law.

The controller calculates the change in energy transferred from the sensor coil to the target material and converts this into a displacement measurement. The advantages are that this method can be used on all electrically conductive, ferromagnetic and non-ferromagnetic metals. The size of the sensor is relatively small compared to other technologies and the temperature range is high due to the resistance measurement of the sensor and cable. The technology is high accuracy and is immune to dirt, dust, humidity, oil, high pressures and dielectric materials in the measuring gap.

However, output and linearity depend on the electric and magnetic features of the target. Therefore, individual linearisation and calibration is required.Maximum cable length is 15m and the diameter of the sensor increases as the measuring range increases.

Capacitive Principle With the capacitive principle, sensor and target operate like an ideal parallel plate capacitor. The two plate electrodes are formed by the sensor and the opposing target. If an AC current with constant frequency flows through the sensor capacitor, the amplitude of the AC voltage on the sensor is proportional to the distance between the capacitor electrodes. An adjustable compensating voltage is simultaneously generated in the amplifier electronics. After demodulation of both AC voltages, the difference is amplified and output as an analogue signal. As the sensor is constructed like a guard ring capacitor, almost ideal linearity and resolution against metal targets is achieved. The technology offers high temperature stability, as changes in the conductivity of the target have no effect on the measurement. Capacitive sensors can also measure insulators.

The technology is sensitive to changes in the dielectric sensor gap and so operates most effectively in clean, dry applications.

Cable length is relatively short due to the effect of cable capacitance on the oscillating circuit tuning.

Laser Triangulation Principle In this principle, a laser diode projects a visible point of light onto the surface of the object being measured. The backscattered light reflected from this point is then projected onto a CCD array by a high quality optical lens system. If the target changes position with respect to the sensor, the movement of the reflected light is projected on the CCD array and analysed to output the exact position of the target.

Measurements are processed digitally in the integral controller and then converted into a scaled output via analogue (I/U) and digital interface RS232, RS422 or USB. Benefits include a small beam spot, long measuring ranges are possible, the sensor operates independent of target material, and a high reference distance between sensor and target.

The method is limited by a relatively large sensor design and a relatively clean optical path is required for the sensor to operate reliably. In addition, for direct reflecting targets, specific sensor alignment/calibration is required.

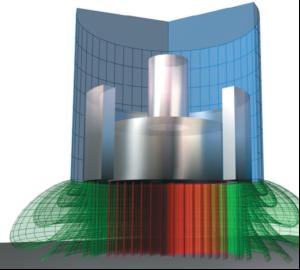

Confocal Principle The technology works by focusing polychromatic white light onto the target surface using a multi-lens optical system.

Lenses are arranged in such a way that the white light is dispersed into a monochromatic light by controlled chromatic deviation. A certain deviation is assigned to each wavelength by a factory calibration. Only the wavelength that is exactly focussed on the target surface or material is used for the measurement. Both diffuse and specular surfaces can be measured.With transparent materials such as glass, a one-sided thickness measurement can be achieved along with the distance measurement. Also, because the emitter and receiver are arranged in one axis, shadowing is avoided. Confocal offers nanometre resolution and operates almost independently of the target material. A very small, constant spot size is achieved.Miniature radial and axial confocal versions are available for measuring drilled or bored holes.

Restrictions include the limited distance between the sensor and target. In addition, the beam requires a clean environment.

Key Selection Criteria: Define clearly what it is that you need to measure and why? In what type of environment will the sensor need to operate? Are there space restrictions? Custom versus off-the-shelf sensors? When considering standard versus custom sensors, improved sensor accuracy often comes from re-calibration, intelligent integrated sensor software, improving the mechanical mounting or by manufacturing the sensor from better components or materials.

Compromising on resolution and accuracy may save you time and money, but will the sensor perform well enough in the application?

The use of non-contact displacement technologies in precision measurement is growing rapidly.

Customers need to measure more accurately, to sub-micron or nanometre resolutions, and against difficult surfaces or materials that cannot be touched during measurements.

These materials include silicon, glass, plastics, miniature electronic and medical components, and food-based surfaces.

This growth has prompted development of new technologies and the adaptation of existing technologies to meet these new measurement requirements and to improve measurement accuracy and resolution. Noncontact displacement sensors come in a wide variety of shapes, sizes and measurement principles. As well as eddy current and laser triangulation sensors, capacitive and confocal sensors are now popular, so it is critical that engineers have a greater understanding of the strengths and limitations of each principle when selecting one for an application.

Eddy Current Principle The eddy current measurement principle is an inductive measuring method. A coil is supplied with an alternating current, which causes a magnetic field to form around the coil. If an electrically conducting object is placed in this magnetic field, eddy currents are induced, which form an electromagnetic field according to Faraday's Induction Law.

The controller calculates the change in energy transferred from the sensor coil to the target material and converts this into a displacement measurement. The advantages are that this method can be used on all electrically conductive, ferromagnetic and non-ferromagnetic metals. The size of the sensor is relatively small compared to other technologies and the temperature range is high due to the resistance measurement of the sensor and cable. The technology is high accuracy and is immune to dirt, dust, humidity, oil, high pressures and dielectric materials in the measuring gap.

However, output and linearity depend on the electric and magnetic features of the target. Therefore, individual linearisation and calibration is required.Maximum cable length is 15m and the diameter of the sensor increases as the measuring range increases.

Capacitive Principle With the capacitive principle, sensor and target operate like an ideal parallel plate capacitor. The two plate electrodes are formed by the sensor and the opposing target. If an AC current with constant frequency flows through the sensor capacitor, the amplitude of the AC voltage on the sensor is proportional to the distance between the capacitor electrodes. An adjustable compensating voltage is simultaneously generated in the amplifier electronics. After demodulation of both AC voltages, the difference is amplified and output as an analogue signal. As the sensor is constructed like a guard ring capacitor, almost ideal linearity and resolution against metal targets is achieved. The technology offers high temperature stability, as changes in the conductivity of the target have no effect on the measurement. Capacitive sensors can also measure insulators.

The technology is sensitive to changes in the dielectric sensor gap and so operates most effectively in clean, dry applications.

Cable length is relatively short due to the effect of cable capacitance on the oscillating circuit tuning.

Laser Triangulation Principle In this principle, a laser diode projects a visible point of light onto the surface of the object being measured. The backscattered light reflected from this point is then projected onto a CCD array by a high quality optical lens system. If the target changes position with respect to the sensor, the movement of the reflected light is projected on the CCD array and analysed to output the exact position of the target.

Measurements are processed digitally in the integral controller and then converted into a scaled output via analogue (I/U) and digital interface RS232, RS422 or USB. Benefits include a small beam spot, long measuring ranges are possible, the sensor operates independent of target material, and a high reference distance between sensor and target.

The method is limited by a relatively large sensor design and a relatively clean optical path is required for the sensor to operate reliably. In addition, for direct reflecting targets, specific sensor alignment/calibration is required.

Confocal Principle The technology works by focusing polychromatic white light onto the target surface using a multi-lens optical system.

Lenses are arranged in such a way that the white light is dispersed into a monochromatic light by controlled chromatic deviation. A certain deviation is assigned to each wavelength by a factory calibration. Only the wavelength that is exactly focussed on the target surface or material is used for the measurement. Both diffuse and specular surfaces can be measured.With transparent materials such as glass, a one-sided thickness measurement can be achieved along with the distance measurement. Also, because the emitter and receiver are arranged in one axis, shadowing is avoided. Confocal offers nanometre resolution and operates almost independently of the target material. A very small, constant spot size is achieved.Miniature radial and axial confocal versions are available for measuring drilled or bored holes.

Restrictions include the limited distance between the sensor and target. In addition, the beam requires a clean environment.

Key Selection Criteria: Define clearly what it is that you need to measure and why? In what type of environment will the sensor need to operate? Are there space restrictions? Custom versus off-the-shelf sensors? When considering standard versus custom sensors, improved sensor accuracy often comes from re-calibration, intelligent integrated sensor software, improving the mechanical mounting or by manufacturing the sensor from better components or materials.

Compromising on resolution and accuracy may save you time and money, but will the sensor perform well enough in the application?

MORE FROM THIS COMPANY

- Recognises colour

- Gauges gaps

- Getting the measure of battery production

- Sensor solutions for predictive maintenance of wind turbines and generators

- Sensing products

- New compact, robust laser sensor with IO-Link interface measures distances to target objects up to 60 metres away

- Sensors put to the test

- Wire sensor ensures water turbine maintains optimum efficiency

- Micro-Epsilon extends high precision 3D snapshot sensors range

- In the picture about temperatures

OTHER ARTICLES IN THIS SECTION