|

Edward Lowton

Editor |

|

| Home> | Premises management/maintenance | >HVAC | >Recovery position |

ARTICLE

Recovery position

25 January 2013

It is possible to achieve excellent air conditioning efficiencies by using heat recovery techniques within industrial settings, as John Durbin, Daikin UK's engineering department manager, explains There are many reaso

It is possible to achieve excellent air conditioning

efficiencies by using heat recovery techniques within

industrial settings, as John Durbin, Daikin UK's engineering

department manager, explains

There are many reasons why increases in air conditioning efficiencies are vital in industry.With heavy penalties on carbon emissions, plus the immediate benefit of lower fuel bills, increasing the energy efficiency of building management systems is a priority for engineers and managers.

Since its introduction in 1982, Variable Refrigerant Volume (VRV) technology has produced excellent efficiencies, while delivering highly versatile solutions for internal climate control. A benefit for industrial environments is that it varies the refrigerant volume within the air conditioning system, zoneby- zone, to match precisely the building's requirements at any moment. This provides accurate control of the temperature in each area, avoiding fluctuations in the internal climate while minimising energy consumption.

As a result, the efficiencies it delivers - typically COPs of three to five - are among the highest currently being achieved in the industry.

However, these are not by any means the maximum levels of efficiency that can be gained from the latest VRV systems when employing heat recovery in balanced mode.

Today, an intelligent approach to heat recovery can deliver efficiencies of up to nine or even 10. In fact a heat recovery system in balanced mode has been proven to deliver a COP as high as10.07*. So how does it work? Like conventional heat recovery, balanced mode operation involves cooling an area of the building experiencing the highest heat gains and transferring that recovered heat to other areas of the building which require heating. By adopting a fully integrated solution such as the VRVIII heat recovery system, heat generated from areas such as plant rooms, production floors and telecoms storage areas can be recovered and reused elsewhere in the building - for the provision of hot water or air curtains, for example.

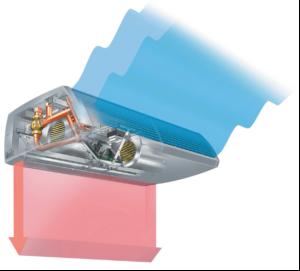

Air curtains provide an effective way to maintain climate separation between different areas of the building, or in entrances where drafts may be prevalent. The Biddle air curtain can be combined with a Daikin heat recovery system to deliver energy consumption savings of up to 67% compared with a typical electrically heated air curtain. The inverter driven compressor allows the capacity to be adjusted precisely to match variations in room and outside temperatures, resulting in less frequent start/stop operations.

It is estimated that this highly energy efficient solution can reduce CO2 emissions by more than 6t and achieve cost savings of £1500 per annum, offering a payback period of just three years.

Heat reclamation units can also be used in the ventilation process. By extracting waste air from a room via the heat exchange process, the recovered heat can then be transferred to the fresh air supply being delivered to that room. The net result is a further reduction in the cooling/heating load on the air conditioning system. Such heat recovery ventilation technology can be included as part of a total heat recovery solution and these highly energy efficient systems can be integrated to provide year round heating and cooling for industrial settings, both large and small.

Given that heat recovery offers such a low cost source of heat and hot water, the aim must be to reject heat only after every other avenue for its use has been explored.

However, it is important that the design process ensures that indoor units are arranged to maximise the occasions when this balanced operation can take place, with the heat recovery system diverting recovered heat to wherever it is needed, thus contributing significantly to the goal of zero heat rejection.

To achieve this, it's vital to analyse right from the start a building's multiple requirements, usage patterns and varying occupancy levels, in order to design a fully integrated system that optimises energy efficiency and heat recovery.

Consultants and engineers should therefore be involved at the earliest possible stages of the design process to incorporate the latest thinking on heat recovery within the building modelling process and to demonstrate the significant impact that integrated heat recovery solutions can have on the reduction of energy usage.

*Based on an REYQ10P in mixed mode at nominal conditions

There are many reasons why increases in air conditioning efficiencies are vital in industry.With heavy penalties on carbon emissions, plus the immediate benefit of lower fuel bills, increasing the energy efficiency of building management systems is a priority for engineers and managers.

Since its introduction in 1982, Variable Refrigerant Volume (VRV) technology has produced excellent efficiencies, while delivering highly versatile solutions for internal climate control. A benefit for industrial environments is that it varies the refrigerant volume within the air conditioning system, zoneby- zone, to match precisely the building's requirements at any moment. This provides accurate control of the temperature in each area, avoiding fluctuations in the internal climate while minimising energy consumption.

As a result, the efficiencies it delivers - typically COPs of three to five - are among the highest currently being achieved in the industry.

However, these are not by any means the maximum levels of efficiency that can be gained from the latest VRV systems when employing heat recovery in balanced mode.

Today, an intelligent approach to heat recovery can deliver efficiencies of up to nine or even 10. In fact a heat recovery system in balanced mode has been proven to deliver a COP as high as10.07*. So how does it work? Like conventional heat recovery, balanced mode operation involves cooling an area of the building experiencing the highest heat gains and transferring that recovered heat to other areas of the building which require heating. By adopting a fully integrated solution such as the VRVIII heat recovery system, heat generated from areas such as plant rooms, production floors and telecoms storage areas can be recovered and reused elsewhere in the building - for the provision of hot water or air curtains, for example.

Air curtains provide an effective way to maintain climate separation between different areas of the building, or in entrances where drafts may be prevalent. The Biddle air curtain can be combined with a Daikin heat recovery system to deliver energy consumption savings of up to 67% compared with a typical electrically heated air curtain. The inverter driven compressor allows the capacity to be adjusted precisely to match variations in room and outside temperatures, resulting in less frequent start/stop operations.

It is estimated that this highly energy efficient solution can reduce CO2 emissions by more than 6t and achieve cost savings of £1500 per annum, offering a payback period of just three years.

Heat reclamation units can also be used in the ventilation process. By extracting waste air from a room via the heat exchange process, the recovered heat can then be transferred to the fresh air supply being delivered to that room. The net result is a further reduction in the cooling/heating load on the air conditioning system. Such heat recovery ventilation technology can be included as part of a total heat recovery solution and these highly energy efficient systems can be integrated to provide year round heating and cooling for industrial settings, both large and small.

Given that heat recovery offers such a low cost source of heat and hot water, the aim must be to reject heat only after every other avenue for its use has been explored.

However, it is important that the design process ensures that indoor units are arranged to maximise the occasions when this balanced operation can take place, with the heat recovery system diverting recovered heat to wherever it is needed, thus contributing significantly to the goal of zero heat rejection.

To achieve this, it's vital to analyse right from the start a building's multiple requirements, usage patterns and varying occupancy levels, in order to design a fully integrated system that optimises energy efficiency and heat recovery.

Consultants and engineers should therefore be involved at the earliest possible stages of the design process to incorporate the latest thinking on heat recovery within the building modelling process and to demonstrate the significant impact that integrated heat recovery solutions can have on the reduction of energy usage.

*Based on an REYQ10P in mixed mode at nominal conditions

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION