|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >Extra qc with new 3d colour camera |

ARTICLE

Extra qc with new 3d colour camera

25 January 2013

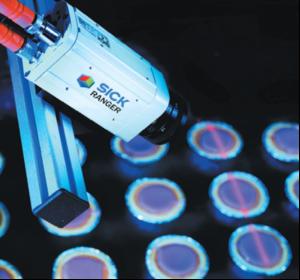

Adbro Controls has integrated SICK's new 3D and colour imaging camera, the ColorRanger E, in a highspeed conveyor-based quality control and high speed reject system. Designed primarily for the food industry, it can ea

Adbro Controls has

integrated SICK's new 3D

and colour imaging camera,

the ColorRanger E, in a highspeed

conveyor-based quality

control and high speed reject

system. Designed primarily

for the food industry, it can

easily be integrated with

existing installations.

Adbro engineer, Nicky Brian, says: "The ColorRanger E has enabled us to deliver a complete palate of inspection parameters for critical QC tasks. Size, height, shape and some surface defects have been possible with previous profiling scanning cameras, however, the new system can inspect for colour defects too.

"With all data combined, the system can replace manual QC inspection, it offers precision inspection down to 0.3mm dia, at speeds to 1m/s, on a 600mm wide belt." A typical system would involve integration of the ColorRanger E with a laser scanner and PLC, which tracks the position of goods on a conveyor belt. The PLC compares scanned defects against pre-programmed range of ideal items for approval or rejection.

Adbro engineer, Nicky Brian, says: "The ColorRanger E has enabled us to deliver a complete palate of inspection parameters for critical QC tasks. Size, height, shape and some surface defects have been possible with previous profiling scanning cameras, however, the new system can inspect for colour defects too.

"With all data combined, the system can replace manual QC inspection, it offers precision inspection down to 0.3mm dia, at speeds to 1m/s, on a 600mm wide belt." A typical system would involve integration of the ColorRanger E with a laser scanner and PLC, which tracks the position of goods on a conveyor belt. The PLC compares scanned defects against pre-programmed range of ideal items for approval or rejection.

MORE FROM THIS COMPANY

- Safe network integration added

- Productivity enhanced

- SICK's FTMg flow meter promises compressed air savings

- SICK expands non-contact linear encoder portfolio

- Safety lock solution

- Sensors: A matter for reflection

- Customisable sensors

- Tamper-proof safety transponder

- 15 minutes of safety

- Tamper-proof safety transponder

OTHER ARTICLES IN THIS SECTION