|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >Infrared heating for chocolate moulds |

ARTICLE

Infrared heating for chocolate moulds

25 January 2013

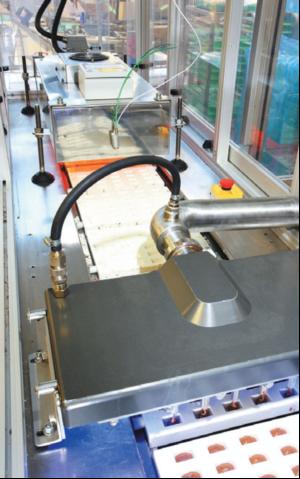

Carbon infra-red mould heating systems from Heraeus Noblelight are helping a specialist chocolatier to maintain the quality of its chocolate products, as well providing significant savings in space and energy costs.

Carbon infra-red mould

heating systems from

Heraeus Noblelight are

helping a specialist chocolatier

to maintain the quality of its

chocolate products, as well

providing significant savings

in space and energy costs.

The production of moulded chocolate involves depositing liquid chocolate into suitable polycarbonate moulds. It is important that the moulds are pre-heated to a specific temperature before the chocolate is deposited.

PID-controlled carbon infra-red heating systems have been installed on all three moulding machines.

Two of the machines run at 2.5m/min (12 moulds/ minute) while the third runs at 3.5m/min (also 12 moulds/ min). All three machines have a pyrometer which regulates the energy of the infra-red emitters to ensure all mould temperatures are about 30°C when filling takes place.

The result has been better temperature control and energy savings of about 60%.

The production of moulded chocolate involves depositing liquid chocolate into suitable polycarbonate moulds. It is important that the moulds are pre-heated to a specific temperature before the chocolate is deposited.

PID-controlled carbon infra-red heating systems have been installed on all three moulding machines.

Two of the machines run at 2.5m/min (12 moulds/ minute) while the third runs at 3.5m/min (also 12 moulds/ min). All three machines have a pyrometer which regulates the energy of the infra-red emitters to ensure all mould temperatures are about 30°C when filling takes place.

The result has been better temperature control and energy savings of about 60%.

MORE FROM THIS COMPANY

- Faster glass tempering

- Heraeus infra-red ensures polymer-polymer bonding in roofing manufacture

- Air rinsing for jam pots

- Dry inks at high speed

- On a mission

- Speeds up heating

- Carbon infrared oven saves time and space

- Infrared module hastens heating

- IR heater helps with hose fitting

- Infra-red heaters

OTHER ARTICLES IN THIS SECTION