|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Pumps | >Hybrid shell |

ARTICLE

Hybrid shell

25 January 2013

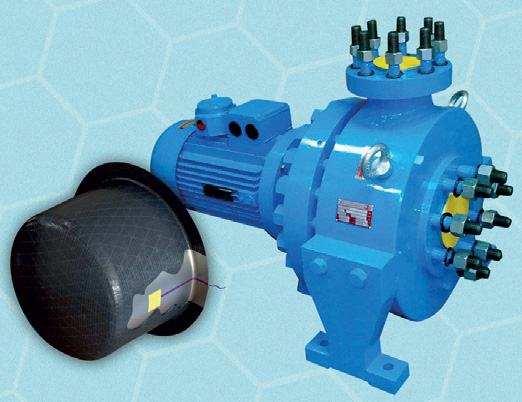

Magnetically driven, sealless pumps from M Pumps S.R.L (previously 3M Pumps) and available from Pump Engineering, are said to offer leakfree, low-maintenance and reliable pumping, especially when the process involves ag

Magnetically driven, sealless pumps

from M Pumps S.R.L (previously 3M

Pumps) and available from Pump

Engineering, are said to offer leakfree,

low-maintenance and reliable

pumping, especially when the process

involves aggressive, corrosive fluids.

To counter eddy current losses, M Pumps has produced a hybrid rear shell design based on an inner shell made from Hastelloy C and an outer shell which consists of a carbon filament wrapped around the steel outer shell. The result is a composite rear shell construction with the properties of a non-metallic material.

Trials have shown its resistance to temperatures above 300°C, pressure resistance to 500 bar and a reduction in eddy current losses by up to 90%.

To counter eddy current losses, M Pumps has produced a hybrid rear shell design based on an inner shell made from Hastelloy C and an outer shell which consists of a carbon filament wrapped around the steel outer shell. The result is a composite rear shell construction with the properties of a non-metallic material.

Trials have shown its resistance to temperatures above 300°C, pressure resistance to 500 bar and a reduction in eddy current losses by up to 90%.

MORE FROM THIS COMPANY

- Pumps for tough transfer tasks

- Sealless design

- Sealless pumps

- High pressure control valves

- Steam water mixer for wash down applications

- Ultra high pressure valve for liquid hydrogen applications

- Easy-clean, quick-strip pumps

- Piston pump handles liquids with high viscosity

- For hygienic applications

- Next generation of smart actuators

OTHER ARTICLES IN THIS SECTION