|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Compressors & ancillary equipment | >Central control |

ARTICLE

Central control

25 January 2013

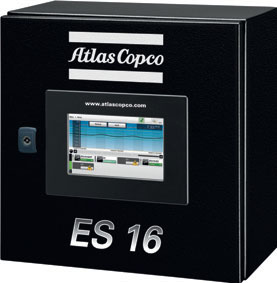

The ES 16 controller from Atlas Copco Compressors can be connected to up to 16 compressors, providing one central point of control for an entire compressed air network as it retrieves and processes information coming

The ES 16 controller from Atlas

Copco Compressors can

be connected to up to 16

compressors, providing

one central point of control

for an entire compressed

air network as it retrieves

and processes information

coming from compressors, dryers

and other measurement equipment.

The result, says the company, is an efficient network that helps to save, on average, 10% of energy use in a compressor room.

Compressors and dryers can be connected to the controller by means of a CAN network. The device stores machine and sensor data for up to one week.

This allows users to see graphs and trends for analysis on the ES user interface and it can also be consulted through the internet.

The result, says the company, is an efficient network that helps to save, on average, 10% of energy use in a compressor room.

Compressors and dryers can be connected to the controller by means of a CAN network. The device stores machine and sensor data for up to one week.

This allows users to see graphs and trends for analysis on the ES user interface and it can also be consulted through the internet.

MORE FROM THIS COMPANY

- Energy economy

- Sony secures savings

- Atlas Copco expands solid desiccant air dryer range

- Atlas Copco Ireland appoints business line manager for its compressor technique service Division

- Low-pressure blowers: Selection matters

- Detects oil risks

- Atlas Copco debuts new smart industrial air compressors

- Plant complies with latest medical standards

- Energy savings for board maker

- A powerful case for compressed air energy recovery

OTHER ARTICLES IN THIS SECTION