|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Bearings | >Bearing problem solved |

ARTICLE

Bearing problem solved

25 January 2013

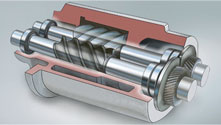

NSK's L-PPS bearing cage technology is providing an effective solution, both in terms of long term performance and cost, for a compressor manufacturer who was receiving complaints about compressor failures resulting fro

NSK's L-PPS bearing cage technology

is providing an effective solution, both

in terms of long term performance

and cost, for a compressor

manufacturer who was receiving

complaints about compressor failures

resulting from damage to bearings

operating at temperatures above 70°C.

NSK recommended use of bearings with cages made from L-PPS (linear polyphenylene sulphide), a glass fibre reinforced plastic designed for high temperature use at up to 190°C. The material has a high level of chemical resistance and thermal stability.

Since the introduction of bearings with L-PPS cages, complaints to the compressor company have ceased.

NSK recommended use of bearings with cages made from L-PPS (linear polyphenylene sulphide), a glass fibre reinforced plastic designed for high temperature use at up to 190°C. The material has a high level of chemical resistance and thermal stability.

Since the introduction of bearings with L-PPS cages, complaints to the compressor company have ceased.

MORE FROM THIS COMPANY

- Reduces machine tool quadrant glitches

- Problem solved

- Longer life bearings for electric motors developed

- Exceeds 1000h

- Added value programme

- NSK academy adds online training module for food and beverage applications

- Mobile robots for quiet locations a reality with NSK’s direct-drive wheel unit

- Centreless grinder uses NSK RA high-precision roller guides

- NSK bearings and training help woodworking machine builder make savings

- Green power for NSK's Europe plants

OTHER ARTICLES IN THIS SECTION