|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Fasteners, springs and adhesives | >Double torsion springs handle car maker's needs |

ARTICLE

Double torsion springs handle car maker's needs

25 January 2013

manufacturer William Hughes has invested in the latest CNC technology machines to fully automate its production process. For many applications, double torsion springs perform better than single and as a result, the

manufacturer

William Hughes has

invested in the latest CNC

technology machines to fully

automate its production

process.

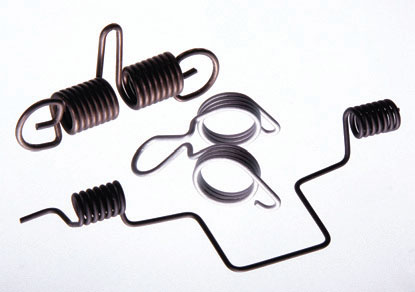

For many applications, double torsion springs perform better than single and as a result, they are widely used in the automotive industry. So when a manufacturer of seat and car interior parts needed a double torsion spring for the door handles of a popular small car, it approached William Hughes. Application engineers designed the spring to meet the exacting specification of the car manufacturer, while ensuring that the spring would be easy to manufacture using its CNC machinery.

The spring is used inside allthe car to return the handle to its normal position and is designed to make assembly into the car mechanism easy.

Despite the complex shape of the central section of the double torsion spring, very little tooling was required.

By making the spring in two fully automated stages, the difficult central section was easily formed to provide a spring that is compact, cost effective and durable. Springs are protected by anticorrosion paint containing zinc flake.

For many applications, double torsion springs perform better than single and as a result, they are widely used in the automotive industry. So when a manufacturer of seat and car interior parts needed a double torsion spring for the door handles of a popular small car, it approached William Hughes. Application engineers designed the spring to meet the exacting specification of the car manufacturer, while ensuring that the spring would be easy to manufacture using its CNC machinery.

The spring is used inside allthe car to return the handle to its normal position and is designed to make assembly into the car mechanism easy.

Despite the complex shape of the central section of the double torsion spring, very little tooling was required.

By making the spring in two fully automated stages, the difficult central section was easily formed to provide a spring that is compact, cost effective and durable. Springs are protected by anticorrosion paint containing zinc flake.

MORE FROM THIS COMPANY

- New capacity springs into action at Wm. Hughes

- Springs: Sole supplier status

- William Hughes celebrates twenty years of growth and customer success at its class-leading Bulgarian factory

- Clean bill of health

- Metrology services for high precision manufacturing

- Electrophoretic painting for protection of metal parts

- Bulgaria success

- Rapid response saves the day for automotive seat manufacturer

- Compression spring fatigue testing machines

- European operations expanded

OTHER ARTICLES IN THIS SECTION