|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Materials | >Strong & flexible wire assembly |

Strong & flexible wire assembly

25 May 2015

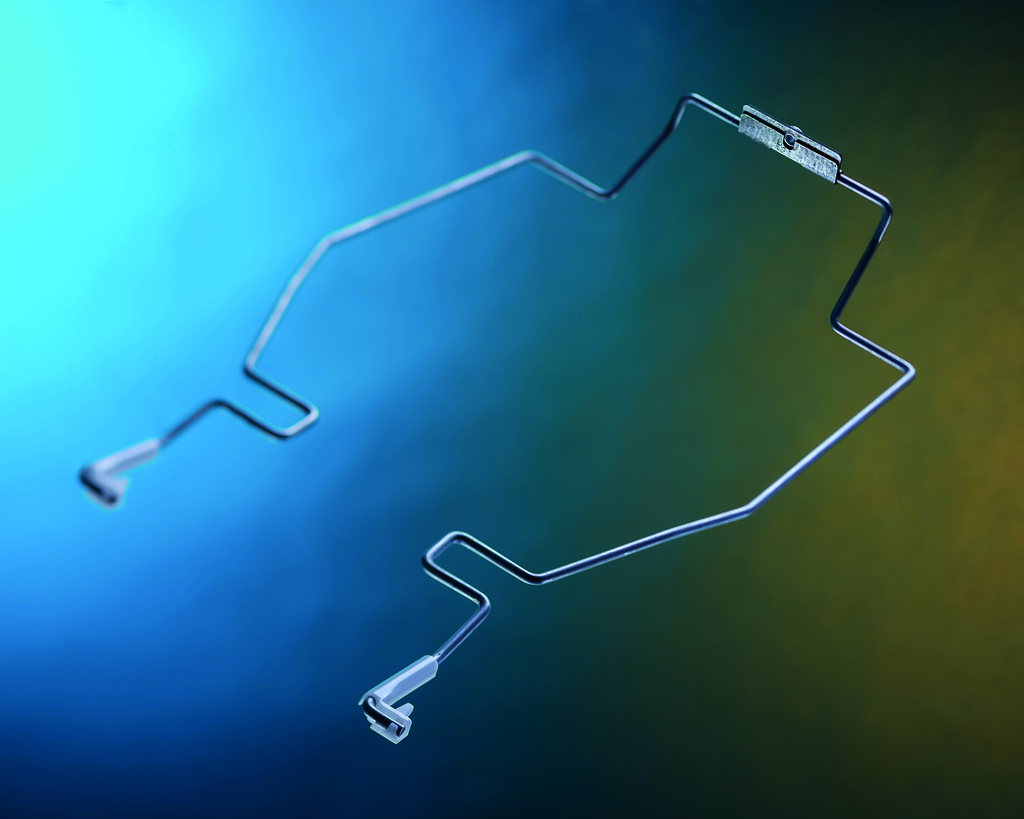

Bent wire components from William Hughes are helping a passenger car manufacturer introduce a high technology version of inflatable bladder seats that can be controlled with air pressure. Used to enhance comfort and provide a massage for passengers in its range of luxury cars, the air system is located in the seat back and features a built-in pump, so small air pockets can be inflated or deflated to suit the needs of the individual.

William Hughes is supplying a wire assembly that holds the air system in place. The assembly has to be both strong and flexible, and manufactured to a fine tolerance.

The assembly, which incorporates several bends situated very close together, also features an adjustable bracket providing flexibility for different seating arrangements.

- Quality cleaning of critical components

- Specialist compression springs

- Salt spray testing keeps check on corrosion

- Protecting parts during storage and transportation

- William Hughes boxes clever with spot welded assembly

- Metrology services for high precision manufacturing

- Insulated bus bars formed without coating damage

- More springs join range

- Strong and flexible wire assembly

- High performance springs for aerospace applications