|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Right-first-time for tube bending |

ARTICLE

Right-first-time for tube bending

04 March 2013

The benefits of all-electric tube bending machines for precision manufacturing will be highlighted by Unison. The companys machines feature a bending system based on precision digitally controlled servomotors. This architecture is said to provide performance benefits in terms of fast and repeatable software-based set-up, plus lower energy consumption and noise.

The benefits of all-electric tube

bending machines for precision

manufacturing will be highlighted by

Unison. The company's machines

feature a bending system based on

precision digitally controlled

servomotors. This architecture is said

to provide performance benefits in

terms of fast and repeatable

software-based set-up, plus lower

energy consumption and noise.

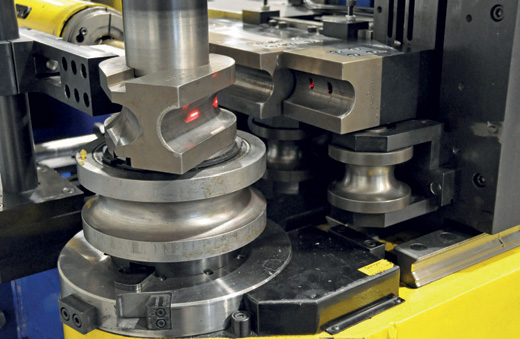

Another feature is a laser-controlled spring-back correction system. This automatically compensates for the natural tendency of metal tubes to 'spring back' slightly after bending, enabling manufacturers to implement right-first-time processes.

A quick-change tooling system will also be on show. Stand P6

Another feature is a laser-controlled spring-back correction system. This automatically compensates for the natural tendency of metal tubes to 'spring back' slightly after bending, enabling manufacturers to implement right-first-time processes.

A quick-change tooling system will also be on show. Stand P6

MORE FROM THIS COMPANY

- Unison mandrel tube bender brings significant performance improvements to new product development at Klarius

- Tube bending cell

- Going slowly round the bend

- Joint venture announced

- Economical bending of tubular parts

- Unison brings pipe bending to Morse Hydraulics

- Tube bending technology on show

- Spring-back demo

OTHER ARTICLES IN THIS SECTION