|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Welding | >Monitors welding operations |

ARTICLE

Monitors welding operations

17 April 2013

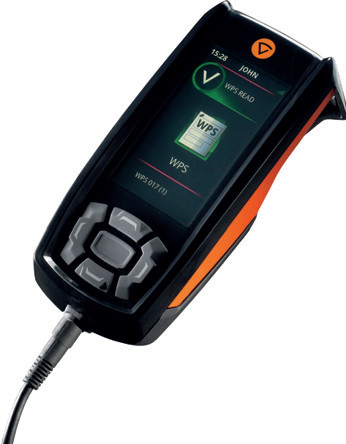

Finnish welding equipment manufacturer Kemppi OY's new advanced welding quality management system is designed to monitor MIG/MAG and TIG welding operations. Called Kemppi Arc System 2.0 - ArcQuality (ArcQ), it is available through Kemppi UK.

Finnish welding equipment

manufacturer Kemppi OY's new

advanced welding quality

management system is designed to

monitor MIG/MAG and TIG welding

operations. Called Kemppi Arc

System 2.0 - ArcQuality (ArcQ), it

is available through Kemppi UK.

Until now many welding projects undertaken in fabrication industries have had minimal qualitative proof that the welding was completed using approved parameters, filler materials and qualified personnel.

The Kemppi Arc System 2.0, module ArcQuality (ArcQ) provides an accurate and formal solution by measuring and identifying WPS deviations outside certain parameters and recording the errors. By comparing the information collected against qualified welding procedure specifications, it provides a solution to define and verify welding quality, avoiding deviations that can result in serious quality issues if left unchecked.

Features include ensuring welders hold valid and up-to-date qualifications, arc and non-arc time reporting, creation of nonconformance reports, automated data collection, welding equipment management tool, anticipates service needs and records service history.

Until now many welding projects undertaken in fabrication industries have had minimal qualitative proof that the welding was completed using approved parameters, filler materials and qualified personnel.

The Kemppi Arc System 2.0, module ArcQuality (ArcQ) provides an accurate and formal solution by measuring and identifying WPS deviations outside certain parameters and recording the errors. By comparing the information collected against qualified welding procedure specifications, it provides a solution to define and verify welding quality, avoiding deviations that can result in serious quality issues if left unchecked.

Features include ensuring welders hold valid and up-to-date qualifications, arc and non-arc time reporting, creation of nonconformance reports, automated data collection, welding equipment management tool, anticipates service needs and records service history.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION