|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Pipes, hoses and fittings | >SWAGELOK JACKETED TUBE CONNECTOR |

SWAGELOK JACKETED TUBE CONNECTOR

13 June 2013

PROTECTS TUBING, ELIMINATES SLEEVES AND SEALING TAPE

SOLON, Ohio (April, 2013) – A companion piece

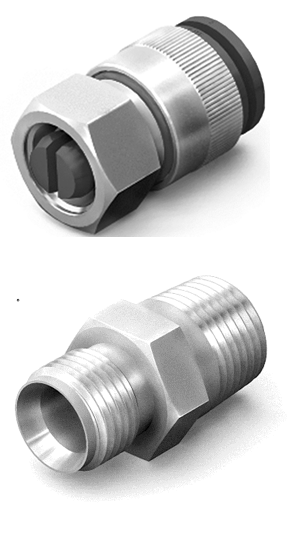

to Swagelok jacketed tubing, the new Swagelok jacketed tube connector (JTC) is

engineered to connect jacketed tubing systems while protecting tubing from

external degradation in corrosive environments. Designed to safeguard against

environmental ingress in the chemical, petrochemical, oil, gas and pulp

industries, the JTC provides a leak-tight, Swagelok tube fitting connection

between sections of single jacketed-tubing, eliminating the need for sleeves

and sealing tape.

The jacketed tube connector’s patent-pending design combines proven tube

fitting technology with an O-ring seal and an innovative,

environmental jacket seal nut; providing a leak-tight seal on the

stainless steel core of the jacketed tubing and a water-tight seal on the outer

diameter (OD) of the jacketed tubing. The JTC design promotes streamlined

installation and high performance, including:

-

Ease of assembly—knurled jacket seal

nut allows for easy, hand-tight assembly.

-

Repeated reassembly—seal performance is

maintained through repeated re-assemblies of the connector.

-

Visual confirmation—jacket seal nut

covers vent O-ring when leak-tight assembly is achieved.

-

Vent port—prevents accidental pressurization

of jacket cavity.