|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine centres and tools | >Clamping solutions |

| Home> | Handbooks | >Manufacturing Matters Ireland | >Clamping solutions |

Clamping solutions

04 November 2013

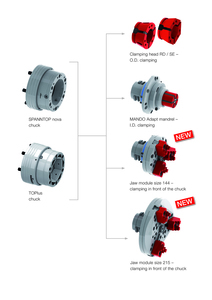

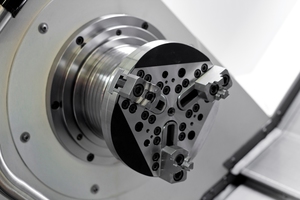

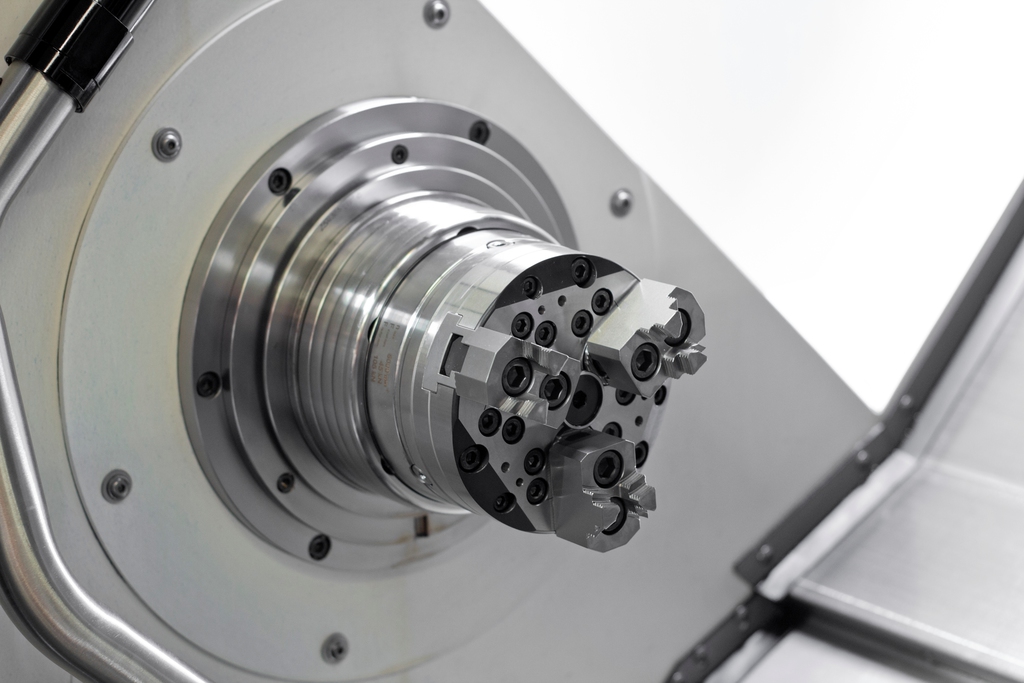

Hainbuch's new Jaw module is a compact unit that converts a standard Hainbuch collet style chuck to a jaw chuck in less than 1 minute.

Mandrels and clamping heads can also be used in the base collet chuck. This new jaw module completes the package and gives a new clamping dimension that is said to offer massive potential for users.

Compared with normal chucks, the company says the Jaw Module offers lower weight and a smaller profile. It also offers a high degree of accuracy. The Hainbuch solution, consisting of a collet style chuck and a Jaw module is compact and as such can efficiently use spindle acceleration and deceleration, saving time and cost per piece; it also lowers the weight on the machine spindle bearings.

• Hainbuch is currently looking for an agent in Ireland,